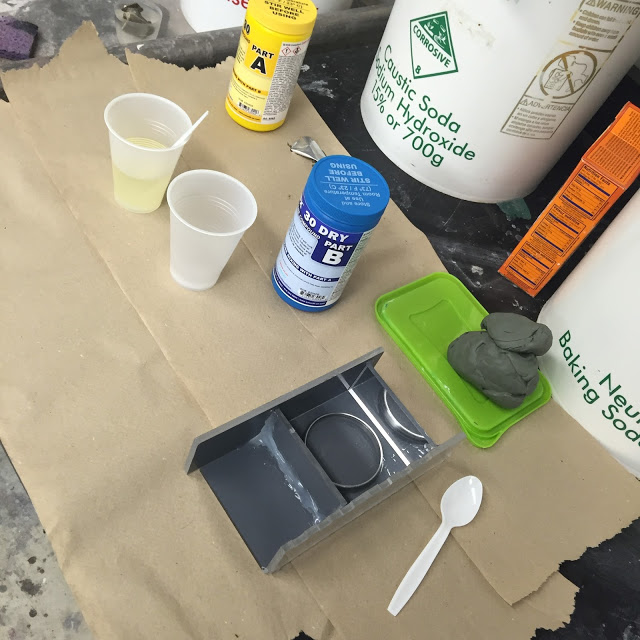

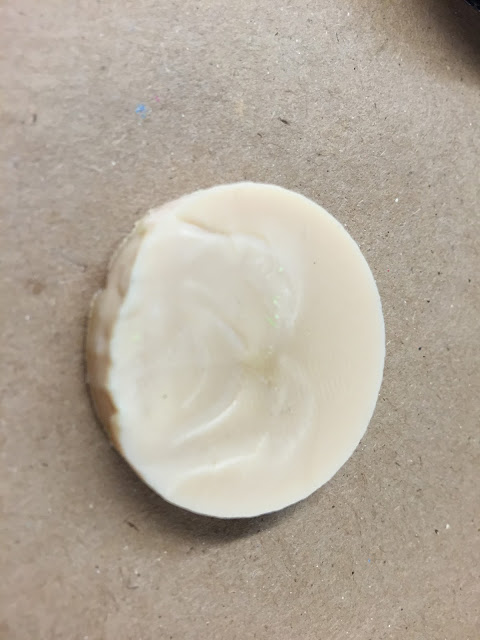

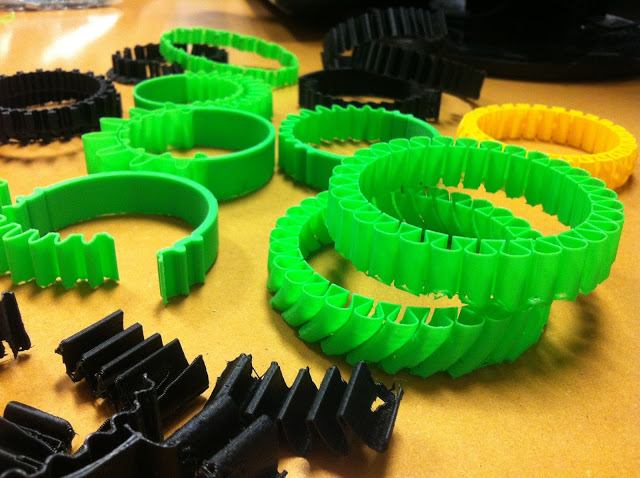

A couple weeks ago I started experimenting with plasti-flex, the material I am casting the iAm sockets out of. This part is currently functioning as an interface with the wall, a transitioning material. The initial mold was created out of a 3D printed prototype and some left over Oomoo rubber. I wanted to test out the plasti-flex so when I heard someone in the studio had some extra rubber, I just quickly grabbed the test print and a Tupperware to make a test mold. The makeshift mold allowed me to quickly test the colors and flexibility of the material. The fit turned out really nice.

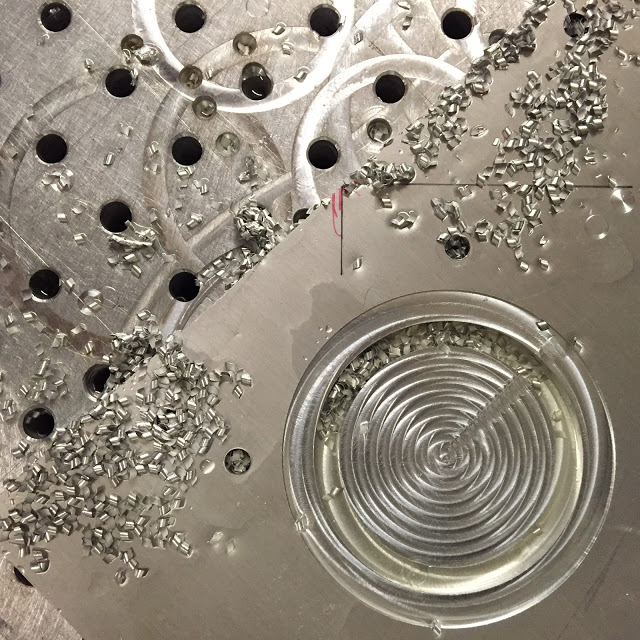

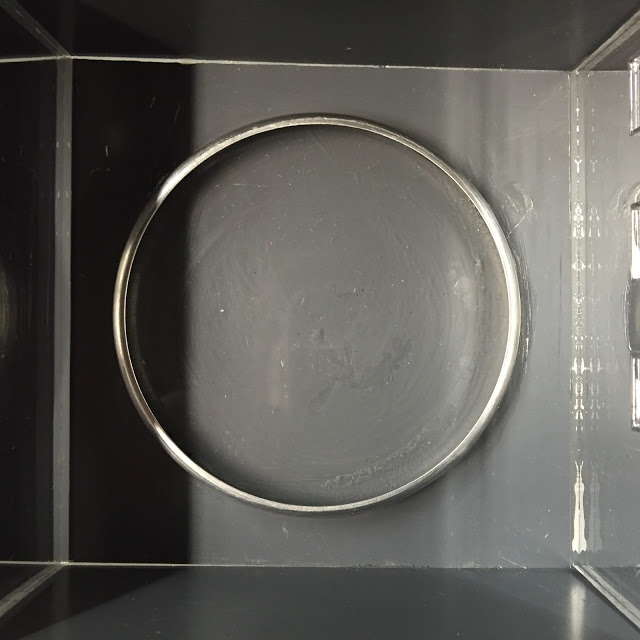

I've since re-designed and machined a new socket piece for the final mold and have poured some ReoFlex30 over it. I should have some really nice sockets once this mold is ready to be used. TBC