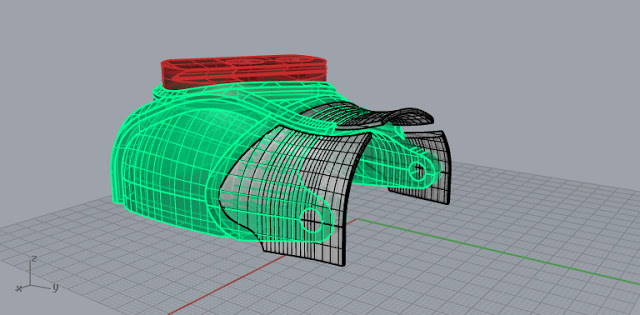

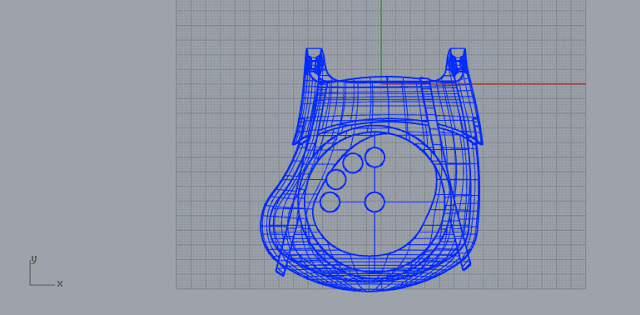

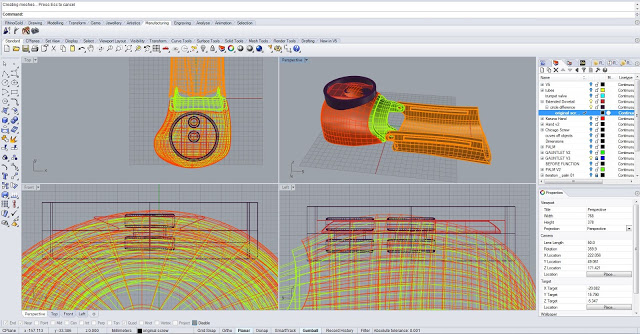

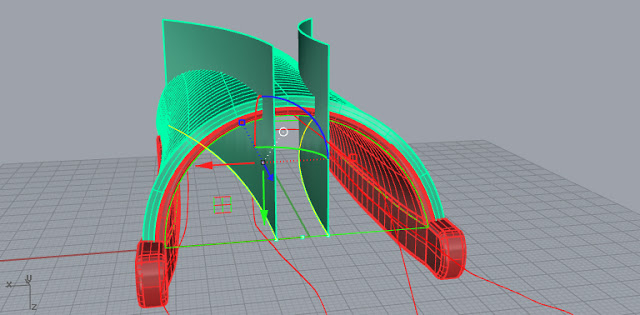

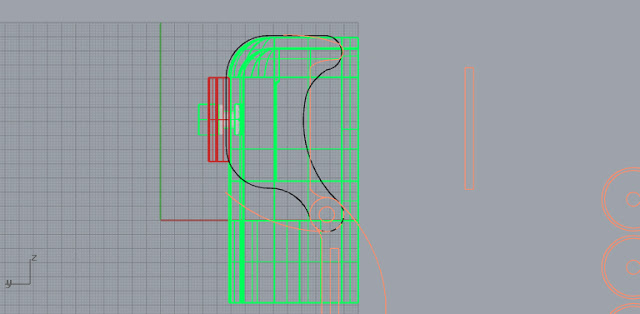

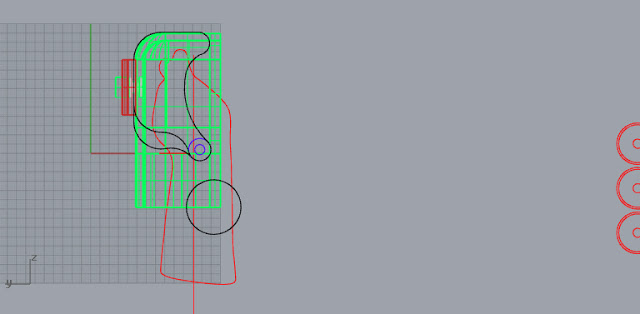

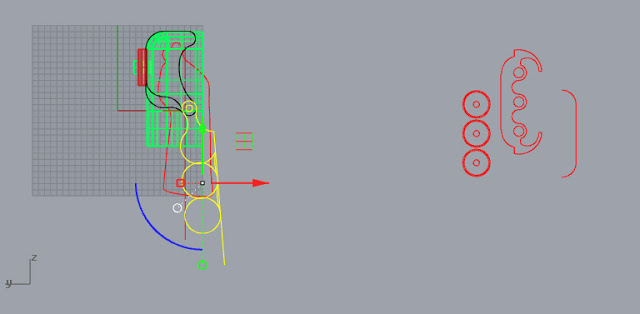

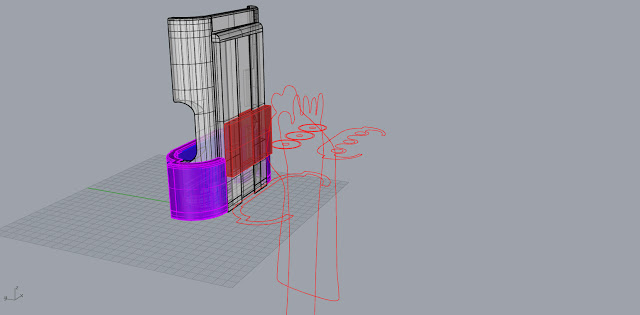

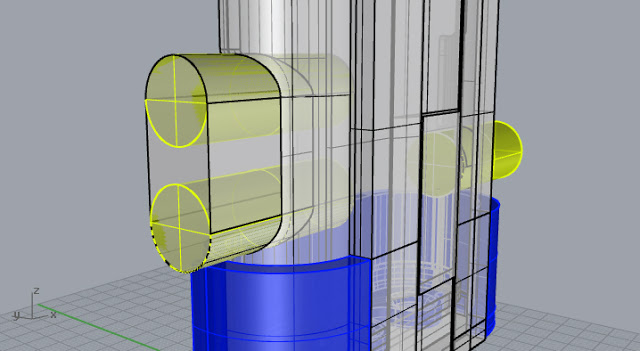

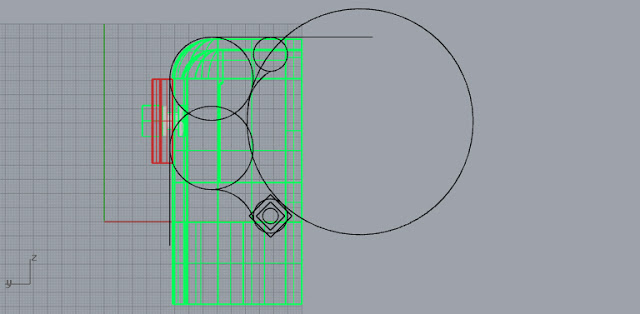

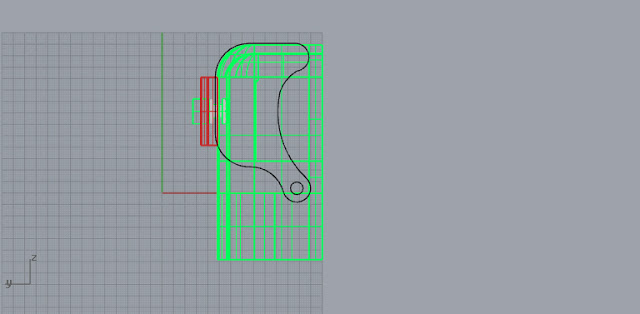

I modified the thickness of the hand/palm piece near the wrist/hinge. I'm trying out two different approaches - one in green and one in blue - the blue one is quite thicker than the green. I am still working with surface offsets to construct any modifications to my designs. I also modified the dovetail slot to have a few more holes to account for a couple more potential angles at which the hand and arm can be positioned.

e-NABLE Fellowship - Karuna's Trumpet Holder - Palm v2

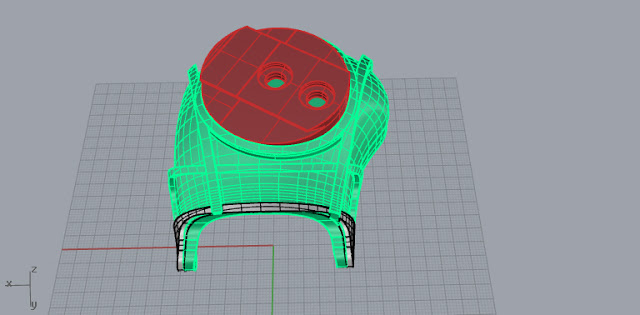

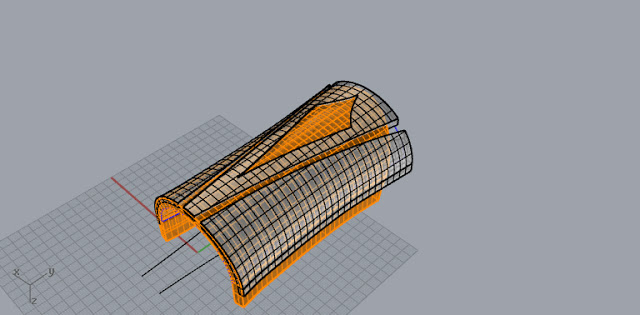

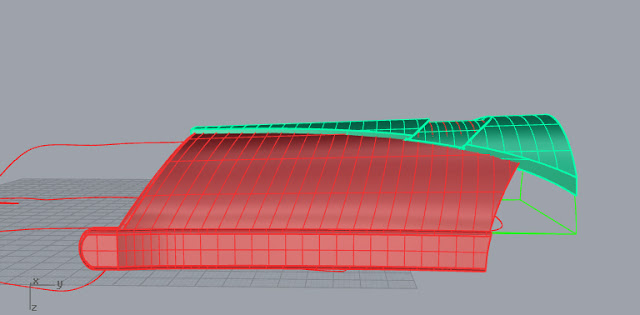

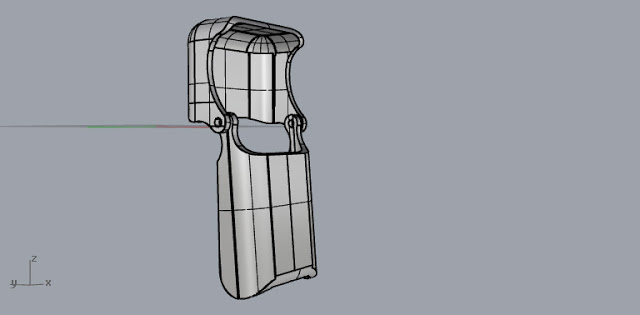

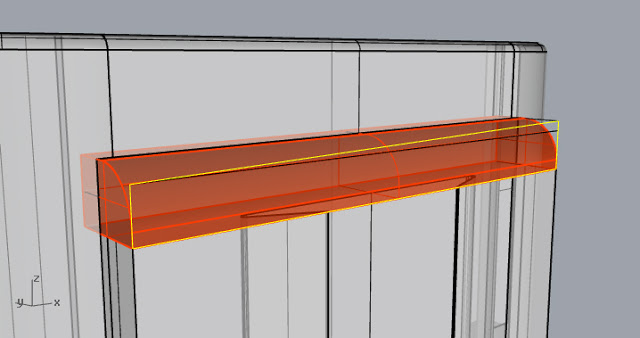

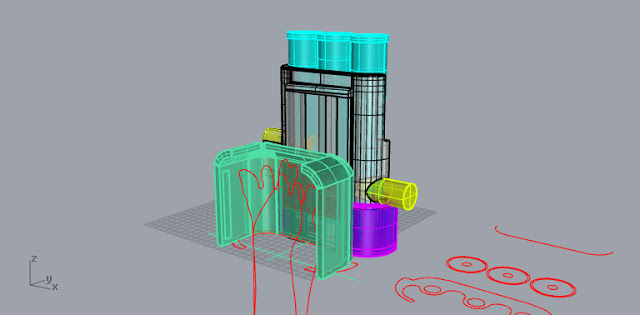

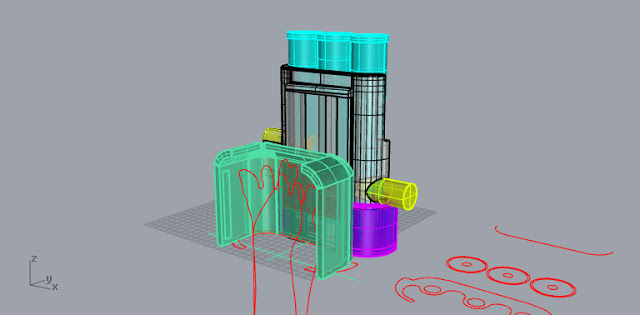

I worked on v2 of the palm/hand today, got through this first iteration on the second design... I need to clean up the design a little bit, but I wanted to get something printed tonight, so I decided to send what I had finished to the printer before I left... I've got a lot of work to do on these parts still but I feel like I'm finally feeling the flow, so I'm confident it will all come together pretty quickly.

I added an extra hole in the hand piece so that the user can adjust the angle at which the hand piece attaches to the trumpet holder... we'll see how it works!

e-NABLE Fellowship - Karuna's Trumpet Holder - Hand/Palm v2

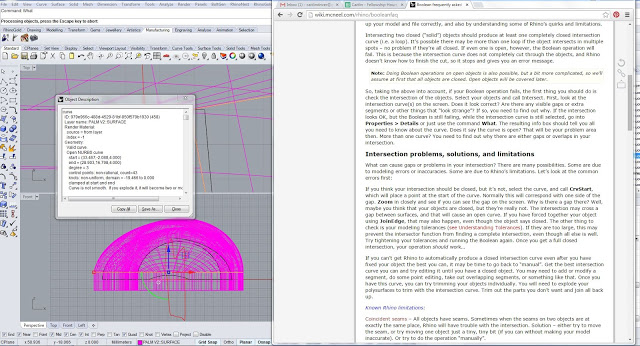

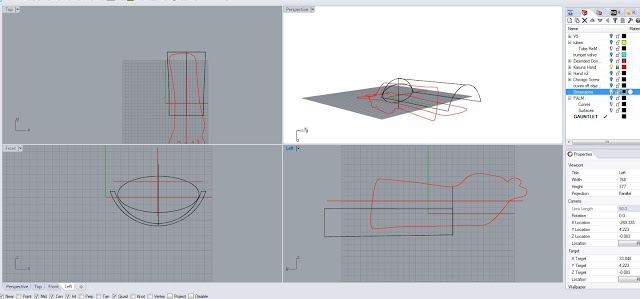

I didn't get as much done today as I would've liked, but I did learn quite a bit about boolean operations. I started drawing hand/palm v2 for Karuna's Trumpet holder, but ran into a few problem right away with curve networks and boolean operations.

After doing some research into why my design might not have been working, I decided to abandon the form and start over with less complicated curves for the palm...

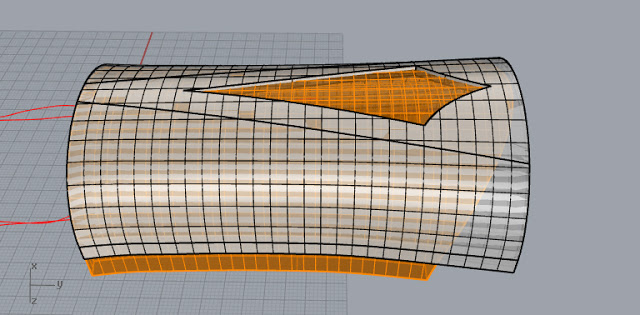

I built this one the exact same way I built the previous, but before boolean-ing I went in and exploded all of the solids and deleted all of the flat surfaces that were "duplicates" on the seam. I'm not sure why this worked and the other way didn't - but it did - so I finally got a rough profile....

I'm currently working on designing the aesthetic surface and the functional parts of the palm... I'm going to keep working on this tomorrow.

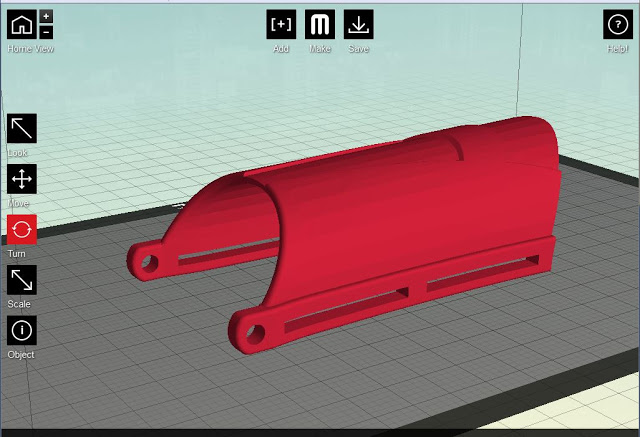

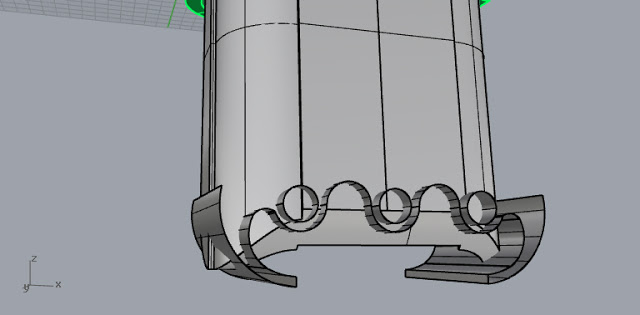

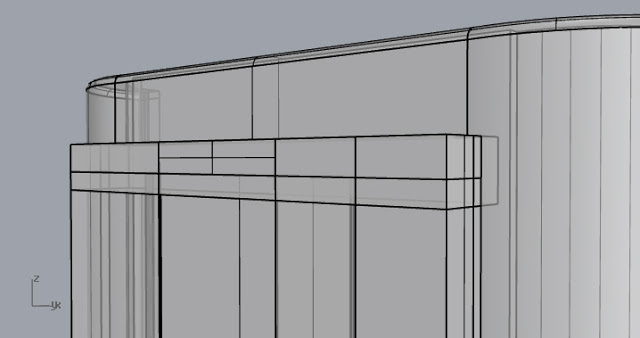

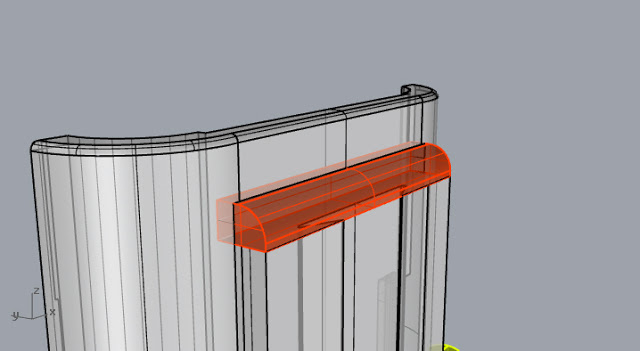

e-NABLE Fellowship - Karuna's Trumpet Holder - Gauntlet v2 vs. Gauntlet v3

v2 ^^^ Doesn't fit on my arm - but you get the idea. The shape here is slightly different than that of v3. I like the way this one feels on my own arm better than the second version - it is more comfortable around the wrist - but that could be because it's just slightly wider.

Before I do v4, I am going to attempt to make palm/hand v2 using the same process.

e-NABLE Fellowship - Karuna's Trumpet Holder - Gauntlet V3

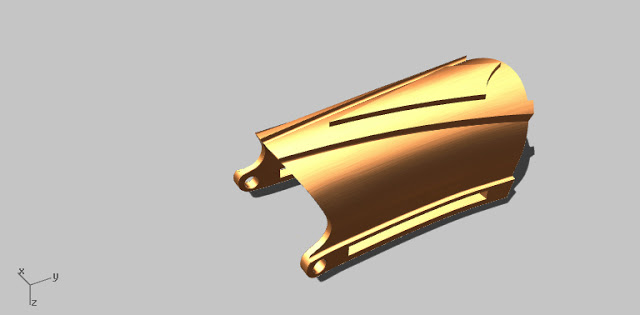

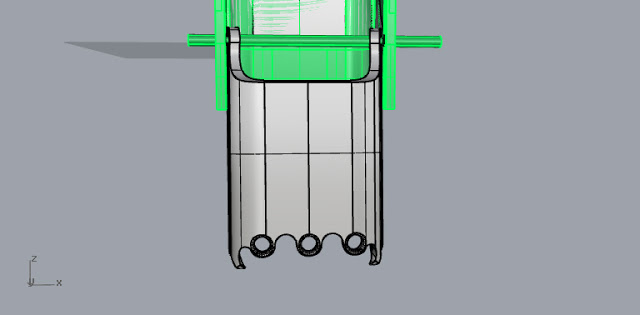

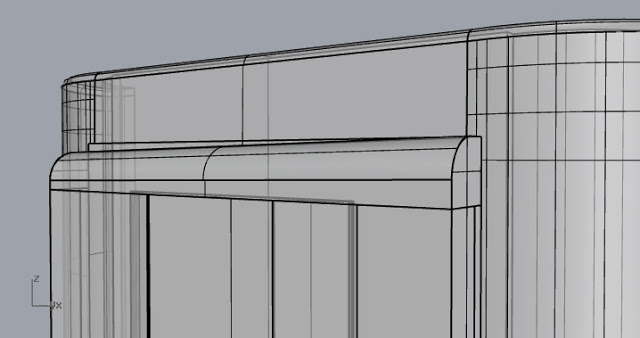

I am continuing to use the same techniques for building the surface detailing on the gauntlet as I had in v2, but I'm working towards integrating the functional parts with the aesthetic parts more fluidly. By offsetting surfaces that eventually are boolean differenced from the surface, I am able to add filets in areas that otherwise would be complicated to filet on the actual model. I have noticed in the print that these areas transition a lot nicer in v3 than in v2.

There are still a few things I'd like to adjust in the form of the gauntlet (both functional and aesthetic), but overall I think these parts are relatively successful considering.

I am also very happy with the process I've found for creating varied surface heights - I am looking forward to spending some time outside of the fellowship developing more complex surfaces for wall relief patterns that can be CNC milled.

e-NABLE Fellowship - Karuna's Trumpet Holder - Gauntlet v2

e-NABLE Fellowship - Midterm Documentation

I can't believe it is already the beginning of the 4th week of my Fellowship with the e-NABLE community. The time has surely flown by.... There has definitely been moments of great success, but of course, those have not come without many revisions in the design process. I have learned so much more about 3D modeling in Rhino than I could have anticipated. Coming into this fellowship, I had only formally taken one class in 3D modeling, which covered the basic techniques for creating form, so I still consider myself to be quite a novice. Most of the objects I have designed up until this point have been relatively simple in construction, but I can see myself progressing rapidly in skill as a result of the challenges I've faced while creating Karuna's Trumpet Holder.

Here are some highlights thus far...

Adaptive Device - Karuna's Trumpet Holder

I've fully designed the attachment mechanism for an adaptive device that will eventually have a palm and gauntlet for a child who plays trumpet. What is exciting about these parts is that the mechanism for attaching a hand and gauntlet is so simple that it could potentially be integrated into many different types of adaptive devices.

**** See some images of the trumpet attachment on the actual trumpet here and here.

The palm and gauntlet have not been developed quite as far as the rest of the design; they are still in need of lots of refinement. These parts are challenging me in a new way. Where the trumpet adapter was fitting on consistent, geometric shapes that lent themselves to be built with solids - Karuna's palm and gauntlet are exactly the opposite, demanding organic undulating curves that are in need of dynamic curve networks in order to fit his body's contour.

I designed a palm and gauntlet (v1) that attached to a dovetail with a Chicago screw, but decided to re-design them both to be more form fitting... I am in the process of re-designing these parts this week. See how far I've gotten.

Looking forward...

Once the final designs for Karuna's hand and gauntlet have been finished, I will be starting on the second set of milestones that I've set for the Fellowship; material and process experimentation for the creation of hands.

"Weeks 4-9: Research, design and prototype with alternative materials and processes for the creation of hands. Materials of interest include; (1) exos shaping technology, (2) silicone rubber molds and (3) cast-able flexible materials. Processes and outcomes of interest include; (1) laser cutting for fabrication and flat-pack design, (2) creating standardized molds for alternative production of 3D printed parts and (3) casting flexible materials to increase potential range of motion, aid in comfort and integration on the wearer. Throughout these tests, design aesthetic and function will be prioritized to facilitate innovation." - Written Plan by Caitlin Driver

Last week, Frankie and Adream had a representative for DJO Global visit the DCRL. They brought with them various products that utilize exos shaping technology. The flexible sheet material used in their products was fun to play around with; it required a brief heating and then was fully mold-able to any desired area on the body. Frankie is investing in some of the material, so I can begin to experiment with it individually and with 3D printed components. I really hope that through the material explorations I can find a new way to design hands effectively without spending the amount of time it currently takes to create hands with 3D printing. I will be posting daily during the week on my blog about my progress.

Here are some highlights thus far...

Adaptive Device - Karuna's Trumpet Holder

I've fully designed the attachment mechanism for an adaptive device that will eventually have a palm and gauntlet for a child who plays trumpet. What is exciting about these parts is that the mechanism for attaching a hand and gauntlet is so simple that it could potentially be integrated into many different types of adaptive devices.

|

| Same setup as above, but opposite side view. You can see more clearly here the holes for the brass tubes and height similarity I was talking about in the previous caption. |

|

| Top shot of the main part and bottom part put together - the valves would be sticking out the top with the palm and gauntlet extending off of the bottom when attached through the dovetail mechanism. |

**** See some images of the trumpet attachment on the actual trumpet here and here.

The palm and gauntlet have not been developed quite as far as the rest of the design; they are still in need of lots of refinement. These parts are challenging me in a new way. Where the trumpet adapter was fitting on consistent, geometric shapes that lent themselves to be built with solids - Karuna's palm and gauntlet are exactly the opposite, demanding organic undulating curves that are in need of dynamic curve networks in order to fit his body's contour.

I designed a palm and gauntlet (v1) that attached to a dovetail with a Chicago screw, but decided to re-design them both to be more form fitting... I am in the process of re-designing these parts this week. See how far I've gotten.

Looking forward...

Once the final designs for Karuna's hand and gauntlet have been finished, I will be starting on the second set of milestones that I've set for the Fellowship; material and process experimentation for the creation of hands.

"Weeks 4-9: Research, design and prototype with alternative materials and processes for the creation of hands. Materials of interest include; (1) exos shaping technology, (2) silicone rubber molds and (3) cast-able flexible materials. Processes and outcomes of interest include; (1) laser cutting for fabrication and flat-pack design, (2) creating standardized molds for alternative production of 3D printed parts and (3) casting flexible materials to increase potential range of motion, aid in comfort and integration on the wearer. Throughout these tests, design aesthetic and function will be prioritized to facilitate innovation." - Written Plan by Caitlin Driver

Last week, Frankie and Adream had a representative for DJO Global visit the DCRL. They brought with them various products that utilize exos shaping technology. The flexible sheet material used in their products was fun to play around with; it required a brief heating and then was fully mold-able to any desired area on the body. Frankie is investing in some of the material, so I can begin to experiment with it individually and with 3D printed components. I really hope that through the material explorations I can find a new way to design hands effectively without spending the amount of time it currently takes to create hands with 3D printing. I will be posting daily during the week on my blog about my progress.

e-NABLE Fellowship - Karuna's Trumpet Holder - Hand Progress - Part 6

e-NABLE Fellowship - Karuna's Trumpet Holder - Hand Progress - Part 5

e-NABLE Fellowship - Karuna's Trumpet Holder - Hand Progress - Part 4

I spent some time today refining the form of the design I had, so that the curves would flow a little better. I am trying to get away from the "block-y" look of the current version I tested this morning... Below are some images of my drawing process, starting from curves and eventually becoming extrusions. Once the form became realized, both the hand and gauntlet, I decided to do a little experimentation with the form. Just some quick tests to see how the piece looked. Overall, I have decided to go back to the drawing board in terms of form and design... After talking with Frankie about the small details I really liked that are part of the actual trumpet's design... I have decided to use those as my inspiration... Stay tuned for more updates tomorrow!

e-NABLE Fellowship - Karuna's Trumpet Holder - Hand Progress - Part 3

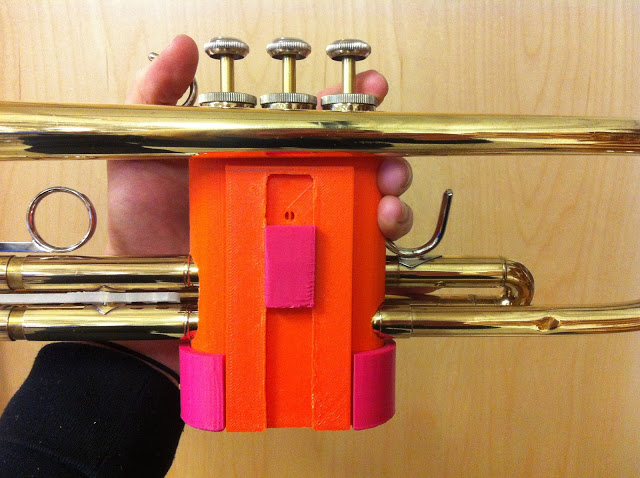

This morning I cleaned up the test hand and dovetail that I printed last night. The piece fits great around the tube at the top of the trumpet. I need to adjust the tolerances around the Chicago screw today, and also add another one for stability. I will test the Velcro slots as soon as I get my hands on some. I didn't take a photo from this angle - but another thing I like is that you can barely see any of the adaptive device from the opposite side. I like the idea of printing these pieces in a clear material eventually to push this even further... To make sure that the instrument and the player's hand and supporting limb remain the most important -with the adaptive device almost undetectable... I wonder if there is a clear alternative material for securing the device onto the hand other than the black Velcro...

e-NABLE Fellowship - Karuna's Trumpet Holder - Hand Progress - Part 2

Above are some images from the beginning of re-drawing the hand piece with solids... I quickly realized that the entire thing should be made with solids and then offset...

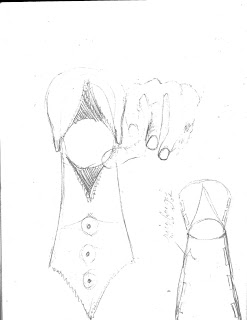

I've started to sketch a profile for the hand piece and gauntlet.

S100 - Visual Inspiration

e-NABLE Fellowship - Karuna's Trumpet Holder - Hand Progress

I put in a short day today because later Bryan Cera is coming in to help me with a project I started last semester. I did get a little bit of work done on the hand part of the adaptive device... I'm not totally sold on the form the hand is taking, but I'm working through it... I've realized that the way I have gone about building the hand piece is the harder way. Looking at what I have modeled now, I wish I would have started from solids.

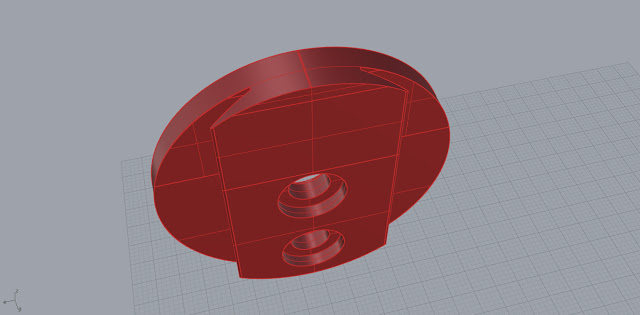

e-NABLE Fellowship - Karuna's Trumpet Holder - Hand

I've started working on the hand part of the trumpet holder for Karuna. This hand will be connected to the red dovetail section (that slides into the main body) by two recessed Chicago binding posts. I've downloaded the models for these screws from McMaster-Carr, to use in the design. I've also started to pull curves off of my existing pieces, so that I can start to recycle those design elements into the hand and gauntlet. I've also really quickly traced images of Karuna's hand to make sure that what I'm designing is the right size for his hand. His hand doesn't need to fit perfectly because there will be padding in the hand, but a general reference is nice.

e-NABLE Fellowship - Hand Designs

Proceeding forward, I will be experimenting with making functional prototypes for certain areas of the design - gauntlet and the fingers. I will also be playing with a few different processes for making the prototypes other than 3D printing, as well as experimenting with material.

e-NABLE Fellowship - Karuna's Trumpet Holder - v5 Rhino Model

e-NABLE Fellowship - Karuna's Trumpet Holder - Not All Prints Are Created Equal

After giving up on the pink filament and adjusting a few of the printer settings...

|

| failure never looked so good |

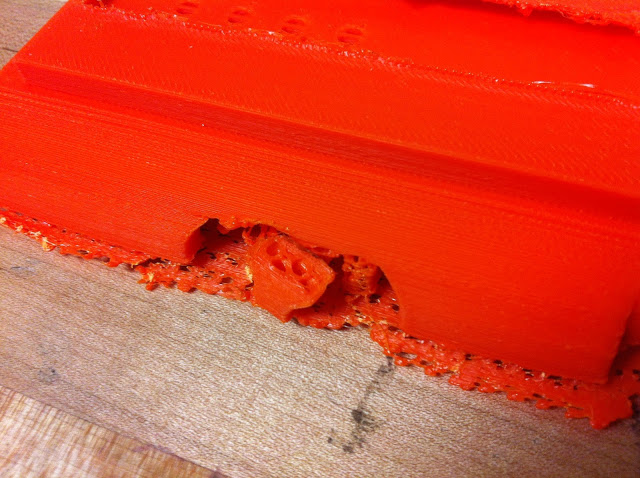

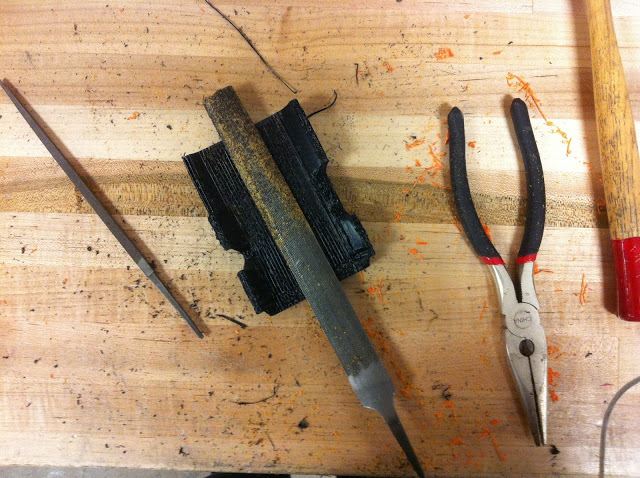

I've finally gotten a few prints of the main part (v4) of the trumpet holder. I had been attempting to print two different versions; one with modeled supports and one with makerware supports...

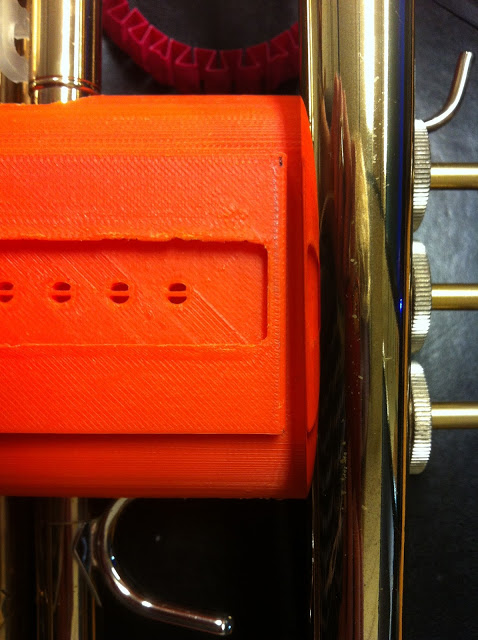

The orange Invetables filament has given me the best results so far. This piece was printed horizontally on the bed, with makerware supports. I'm happy with the quality of this print - the tolerances are on point.

The black Hatchbox filament is printing well, but I'm getting a lot of warp-age... This could be due to the filament or the vertical flat placement on the print bed. I'm doing another test print in black today so I will compare the results. The above image shows the larger gaps between the pink piece and the brass tubes.

e-NABLE Fellowship - Karuna's Trumpet Holder - Design Revisions

The prints I've been getting of the main part are in need of a few design revisions... The piece between the two brass tubes on the left of the main piece is having a hard time printing, So tomorrow I will take this part out since the piece is rather secure on the trumpet without it.

With the makerware supports, there is quite a bit of clean-up on the inside... But, as long as it's cleaned well, the piece fits.

The set of parts that are attaching the hand piece to the trumpet are really low profile and strong.

I will try closing the gap between the pink piece and the bottom of the brass tubes.

The valve oil fits in the holes on the bottom piece with plenty of room to spare.

I'm going to try two different versions of the dovetail design tomorrow. I also think I'm going to scratch the pegs all together... I thought that these would be a nice customization aspect of the design - but for now they are superfluous.

e-NABLE Fellowship - Karuna's Trumpet Holder - Hand & Gauntlet

I've started thinking about designs for the hand and gauntlet attachments for the trumpet holder.

It's important to me that these components will fit in the bottom of the trumpet case, and be easy to take on and off of the mount with one hand... The hand will have the dovetail insert attached to it at the palm and will Velcro over the back of the limb.