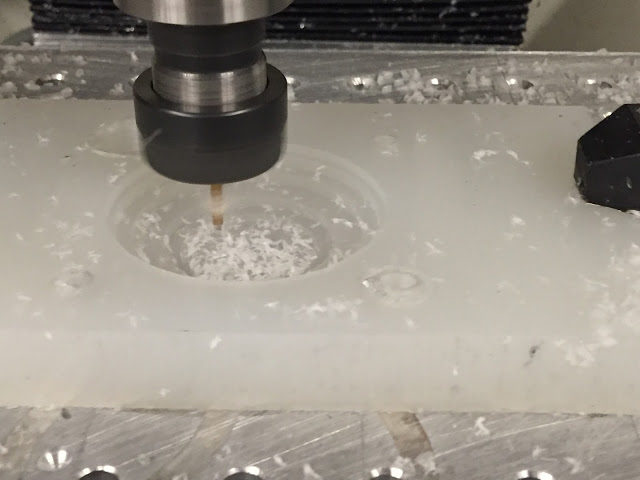

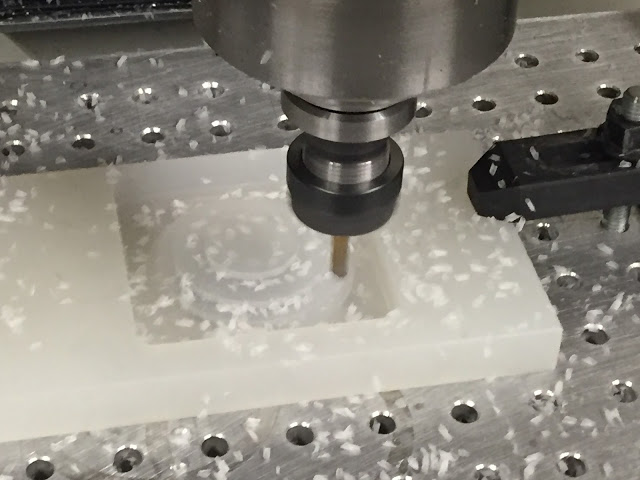

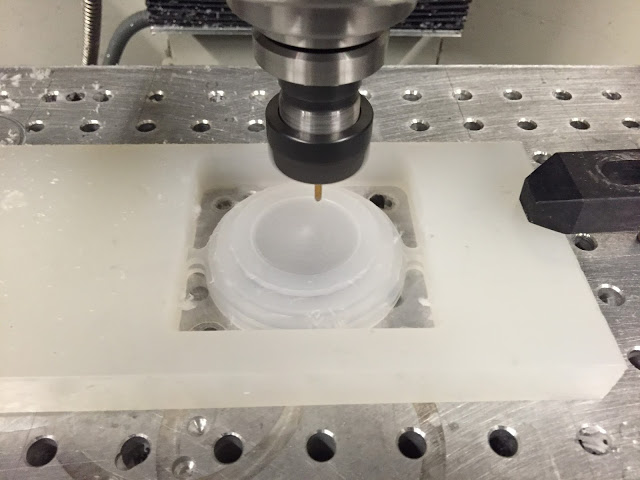

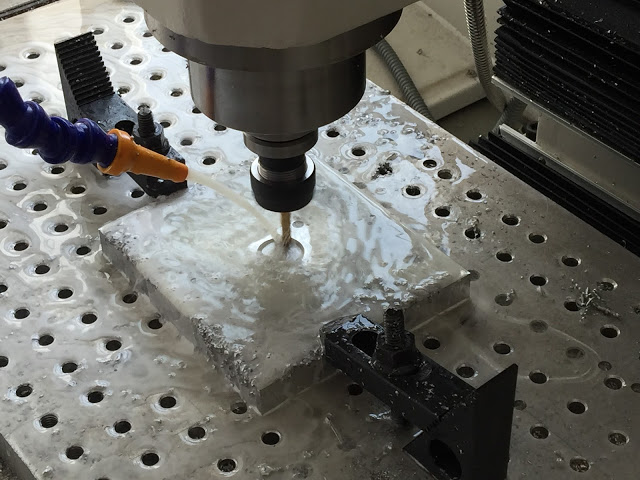

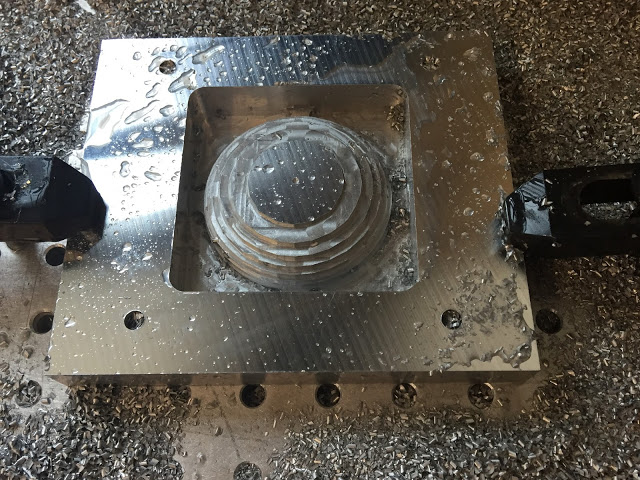

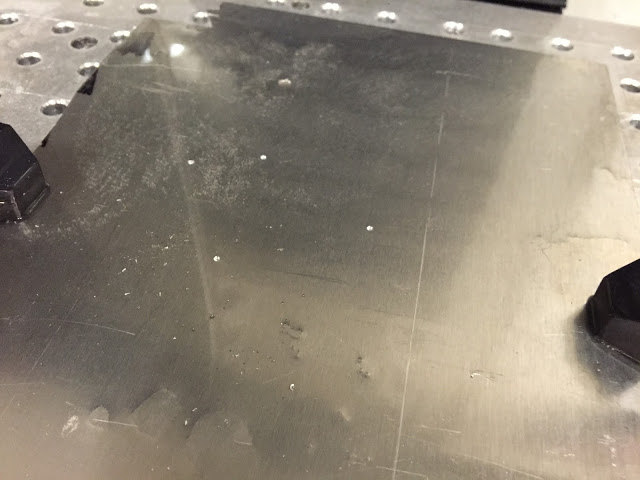

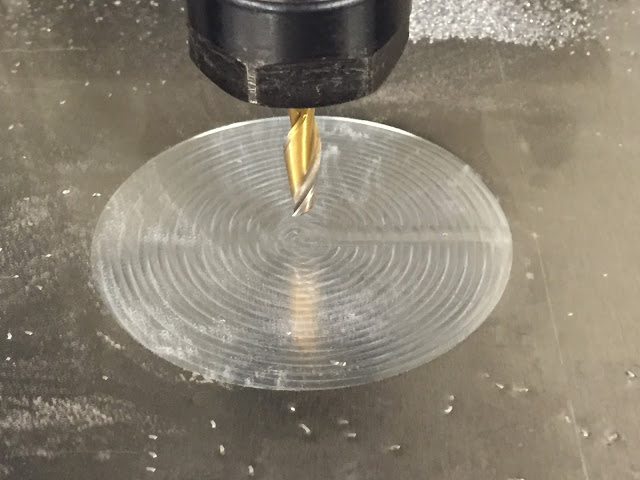

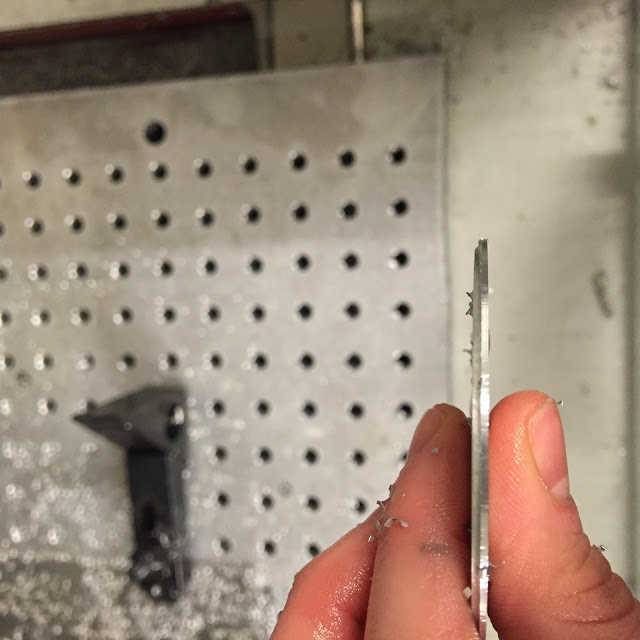

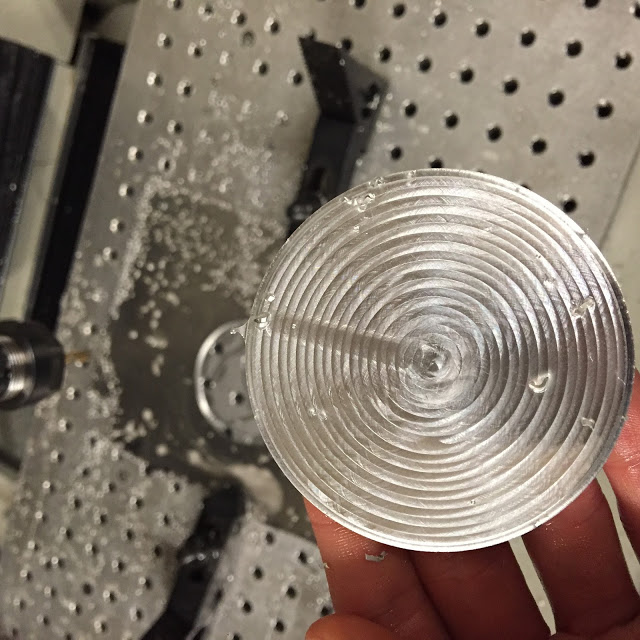

This weekend I machined a version of the iAm light out of polypropylene. I ran into a few issues with the break-chip drill operation, but luckily nothing detrimental. This series of operations only takes about an hour and a half, a significantly less amount of time than the aluminum versions of this shape (5 hours per piece, yikes!). I'm going to test out sandblasting on the back of the light to see if that diffuses the light a little more. I've got a 12 neopixel ring, trinket, and battery that all goes inside, so I'd like to be able to frost the dome a little more, so that the electronics don't distract. I've been thinking about the color of light I'd like the object to emit, and I think I've decided on hues of orange to go with the plugs. I'm really having a lot of fun with this project, all of the materials and all of the components are making it challenging to finish quickly, but I think taking my time with some of the decisions will pay off in the end product.

iAm - milling aluminum

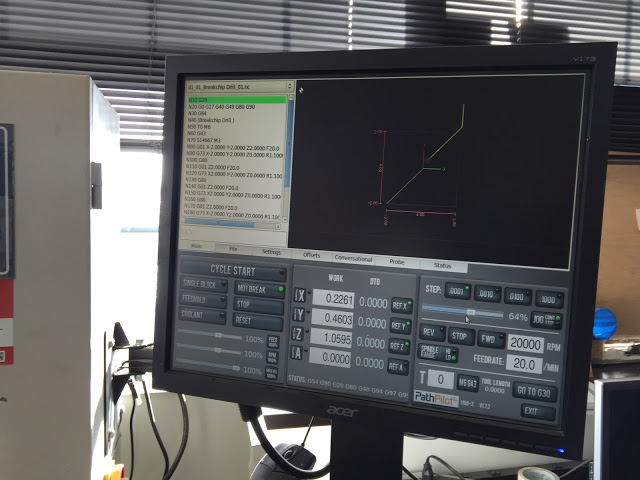

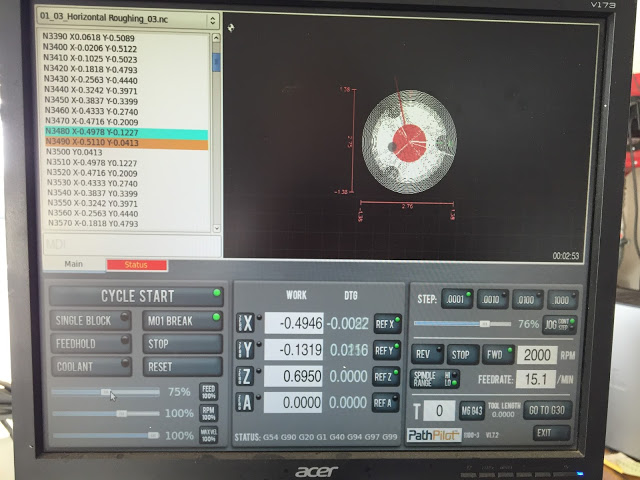

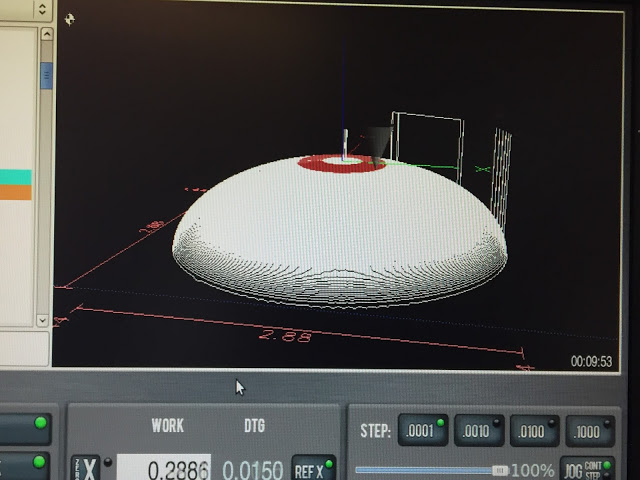

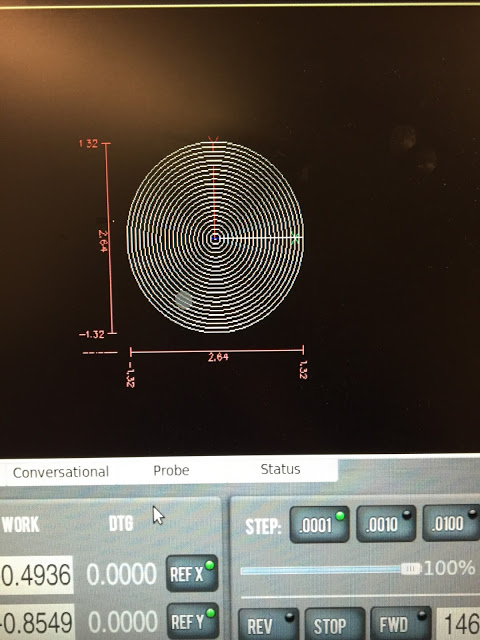

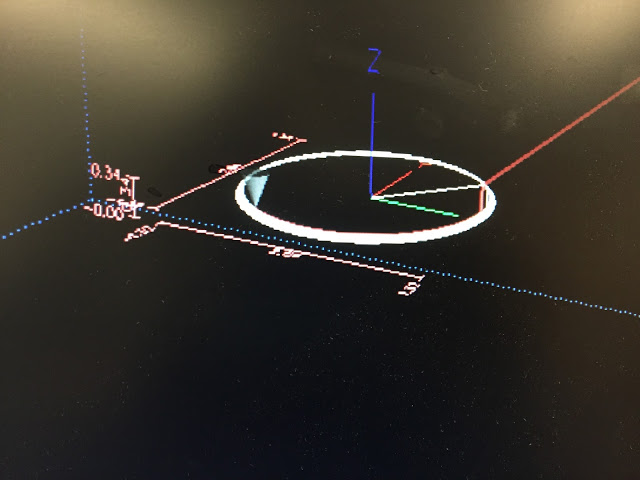

Frankie showed me how to use the tormach with pathpilot last week. He helped me mill the top portion of iAm, and then over the weekend I wrote the code and milled the bottom half. The tolerances between the top and bottom are just right - makes me super happy!!! I will finish assembling this next week.