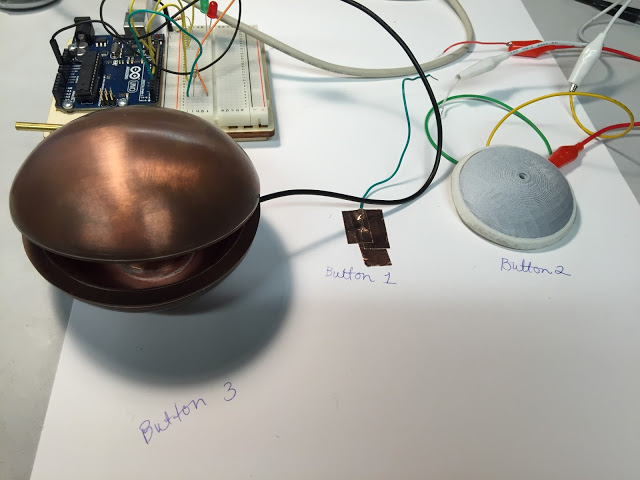

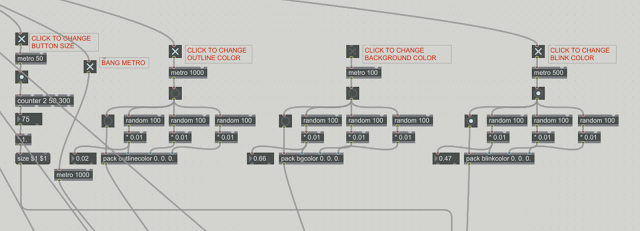

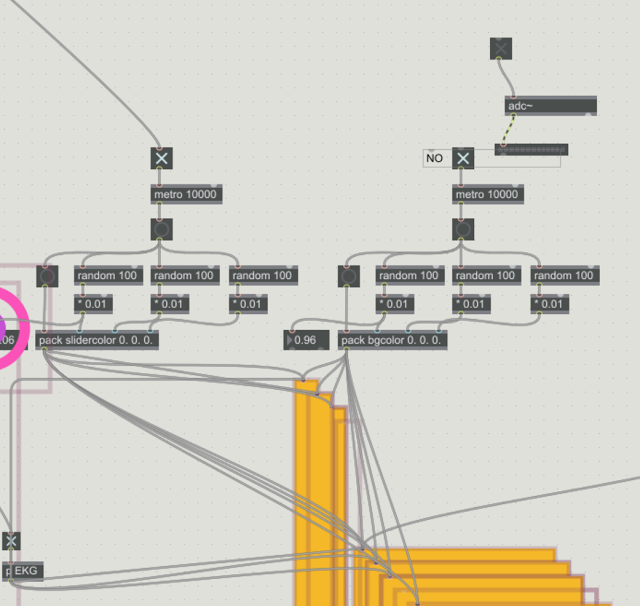

I am manipulating a few images of water that I recorded out at Atwater Beach last week for my final project in Interactive and Multimedia Art. I've been doing some writing about the work, so I'll just post that here too (below)... I'm not sold on the video presentation yet - so I'm not posting any video documentation until that's better under my control. To see the work live, check out Arts Tech Night at Kenilworth Square East on Wednesday, December 16 from 6PM - 9PM.

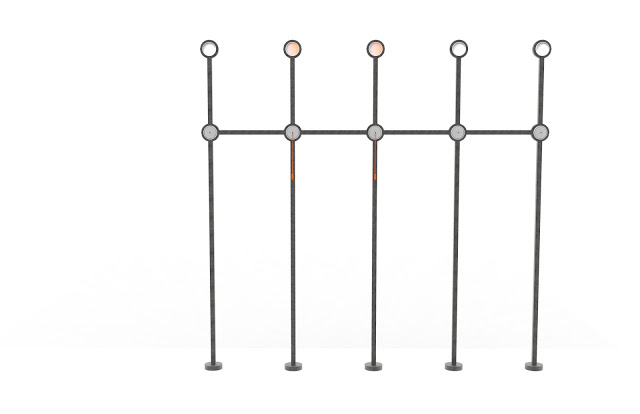

Bound by Periphery

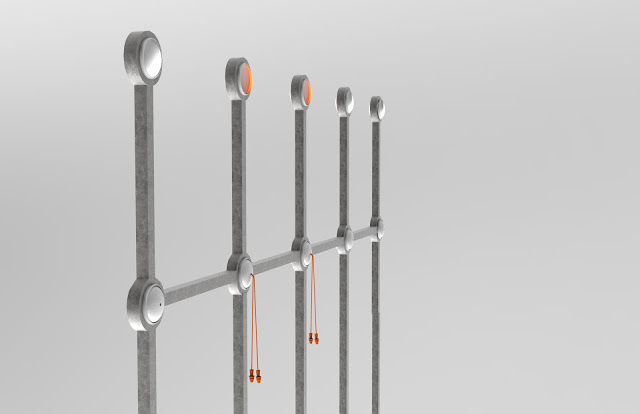

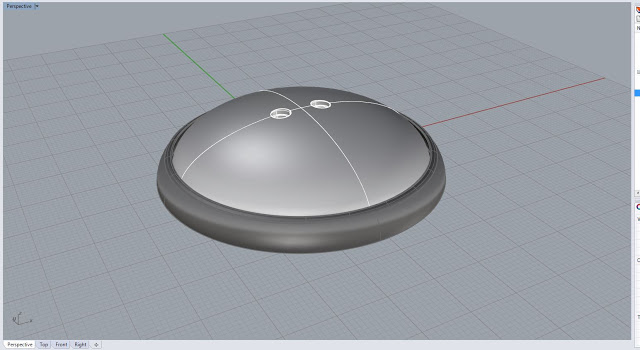

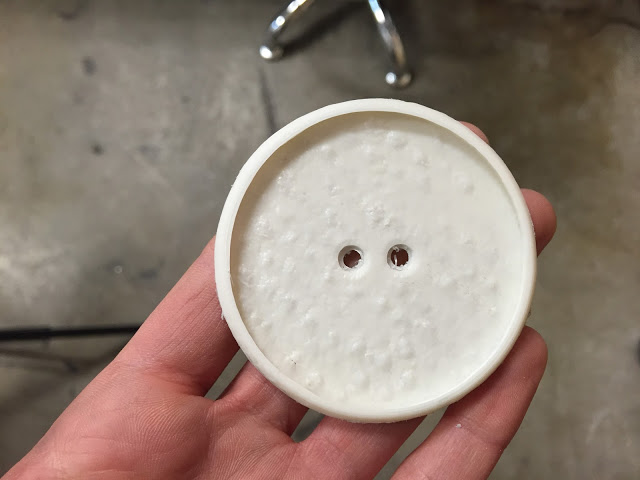

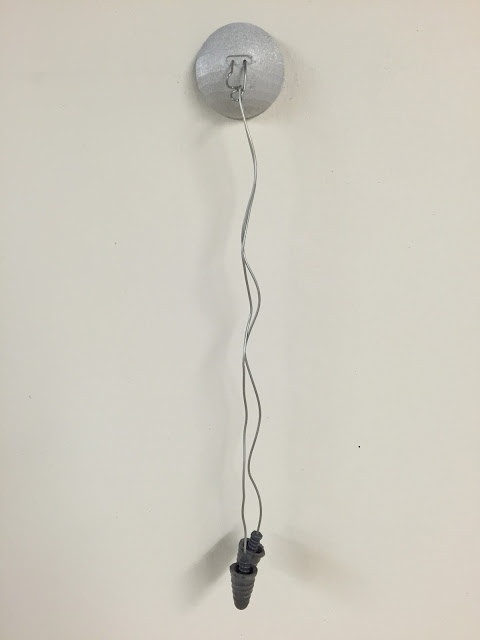

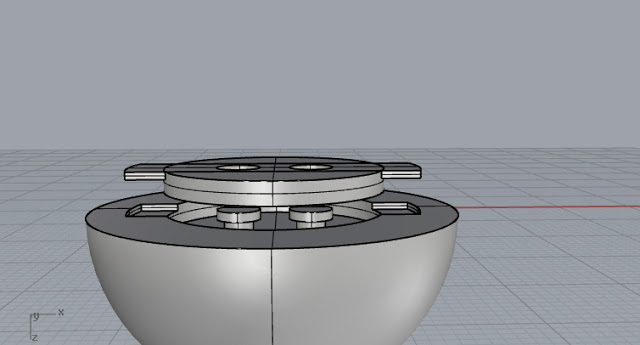

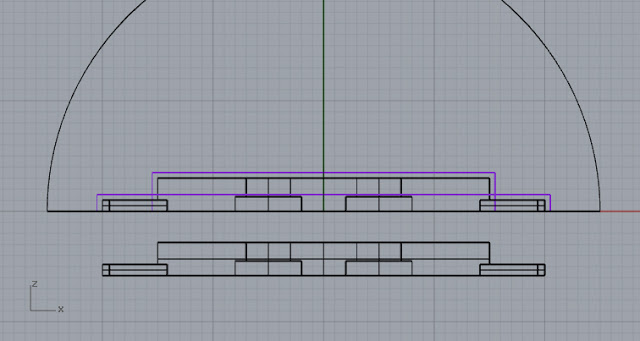

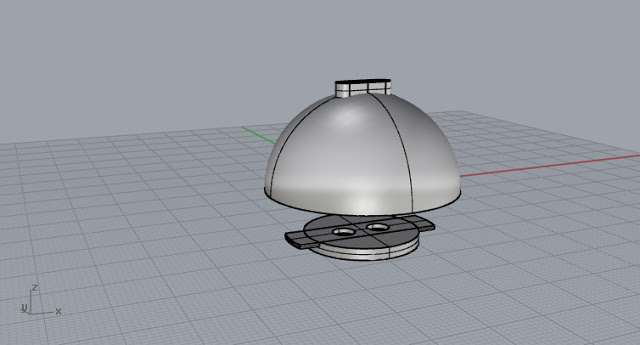

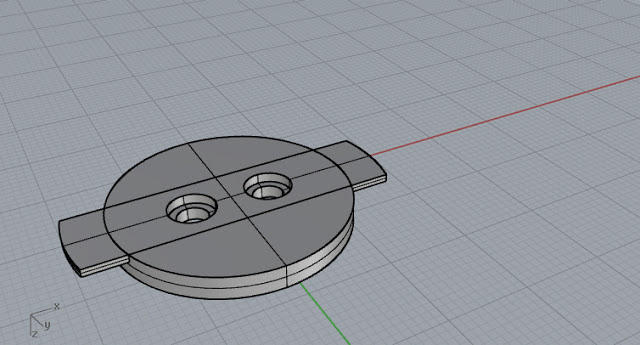

is an interactive art object that explores aspects of peripheral awareness

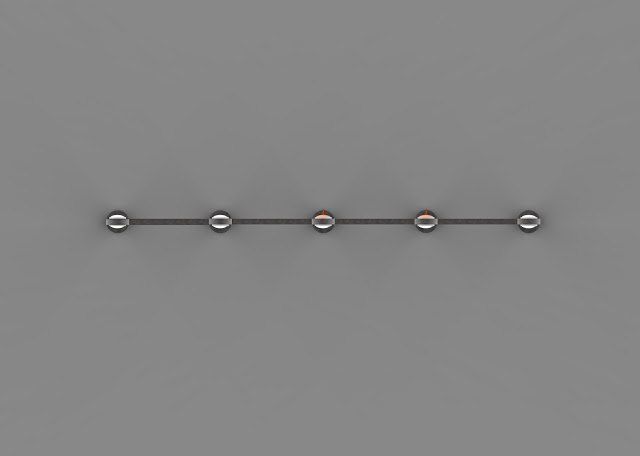

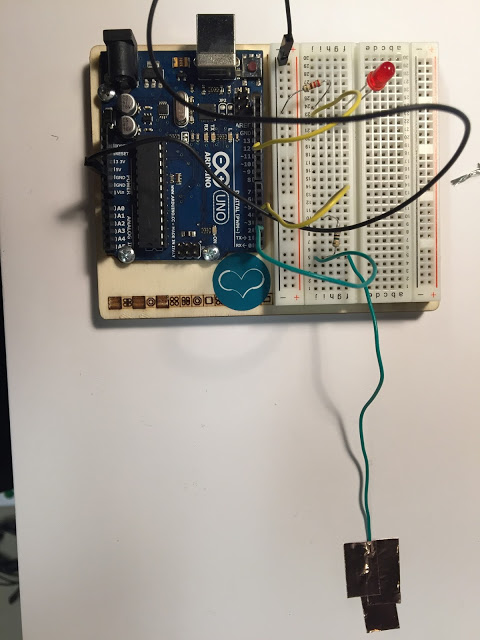

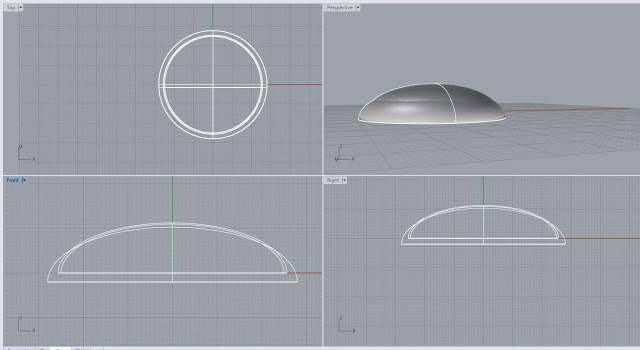

through human presence and touch. Upon approaching the object, the viewer’s

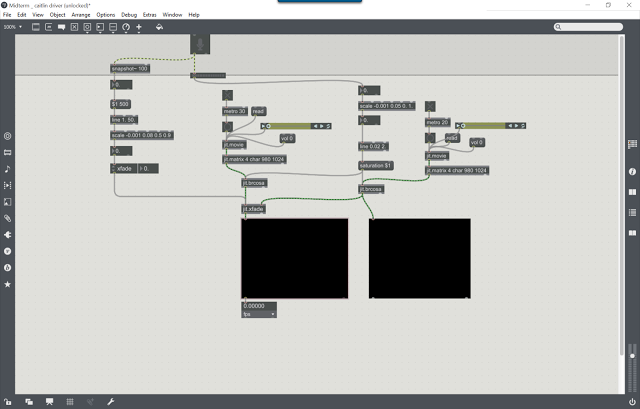

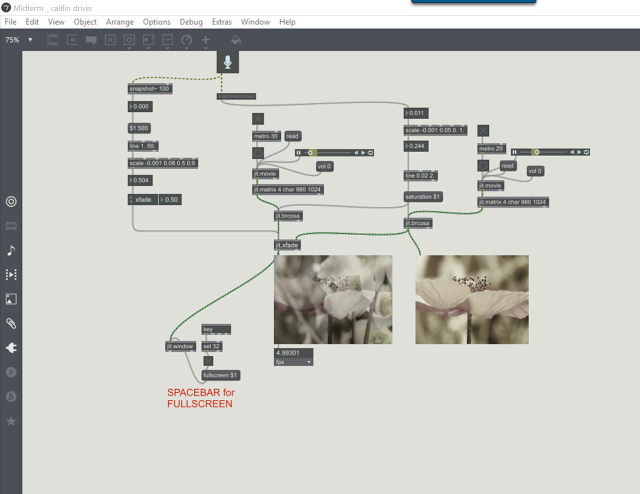

presence and proximity are sensed; this reveals a moving image on a screen

resting face up on the gallery floor. By crouching down and physically

exploring the frame of the video, the imagery begins to change; the water

imagery becomes clear, colors increase in saturation and the sound of waves and

wind becomes evident. Through presence and an acute awareness of the boundaries

of the object, the viewers experience becomes more dynamic and descriptive. In

this way, Bound by Periphery explores

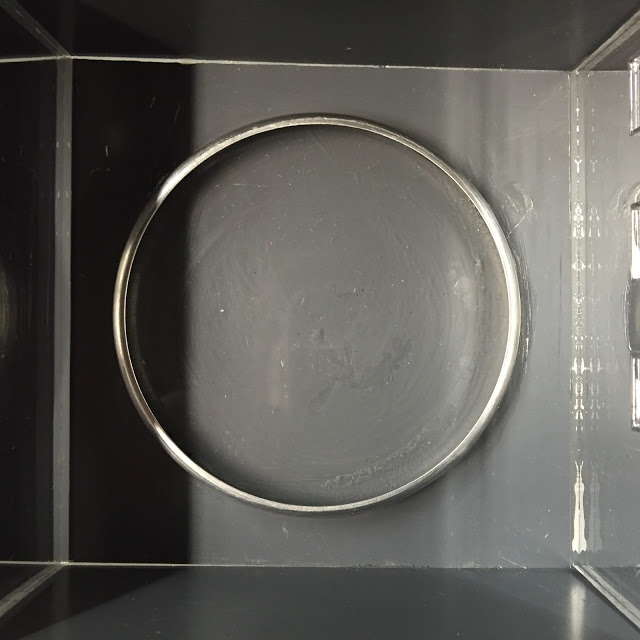

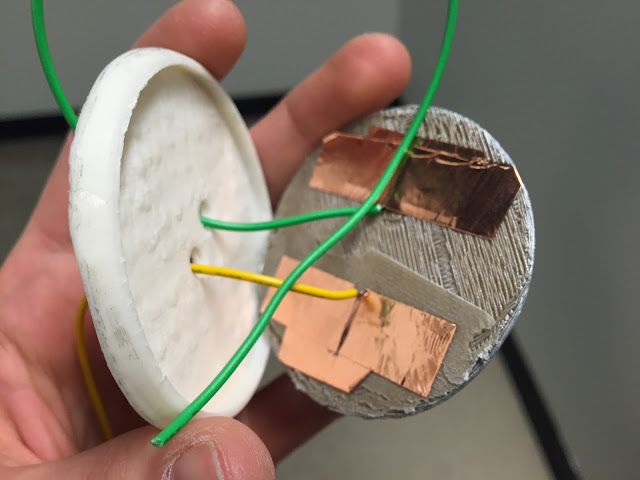

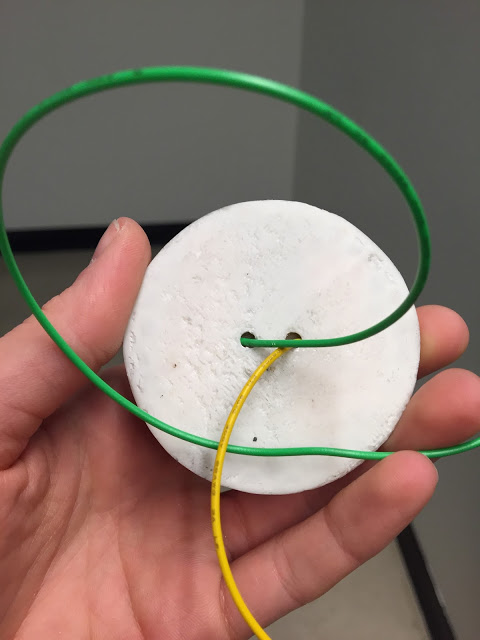

various states of being contained and containing physically through objects as

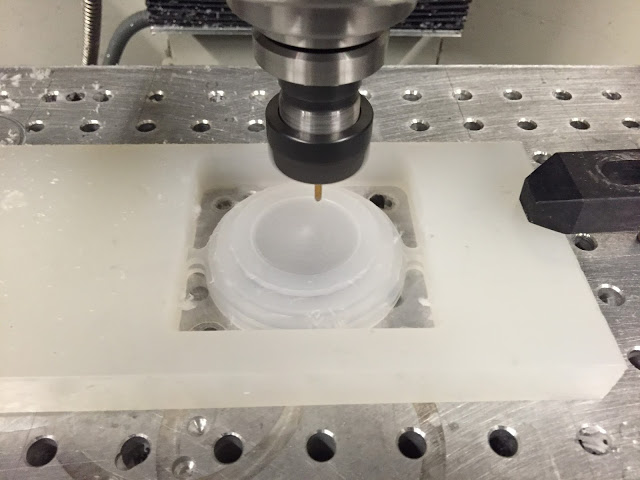

a metaphor for the mind. A container holds a screen, holding a sequence of

video frames, playing over time. While screens can contain an endless amount of

data, this object is restrained to the frame of the video. The video frame only

allows us to experience what is in view, limiting our field of vision, but upon

exploration of the periphery, the focus becomes clearer and transforms. By

placing emphasis on the physical presence of the body on the edge of the

object, the viewer is offered an incentive to explore, to relieve themselves of

tunnel vision, to soften focus and play.