Last week I installed a number of the iAm series pieces "buffet style" in a gallery space. I invited some friends in and asked them to interact with the pieces. The event resulted in some new inspirations and a lot of laughs.

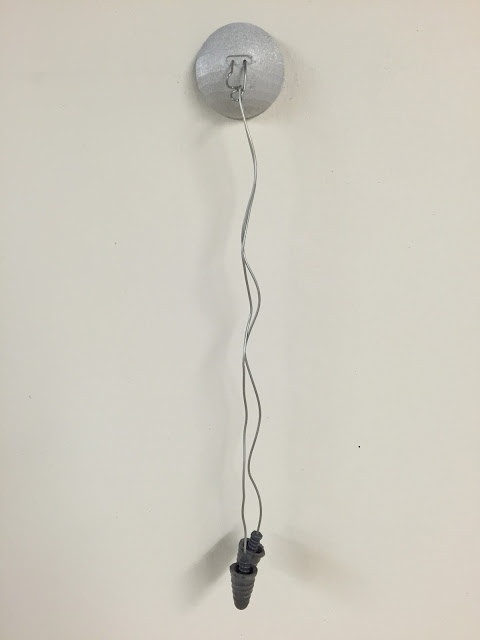

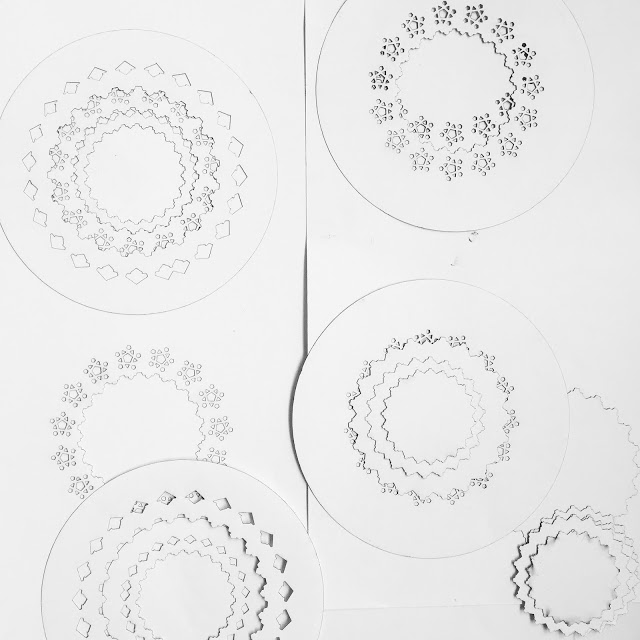

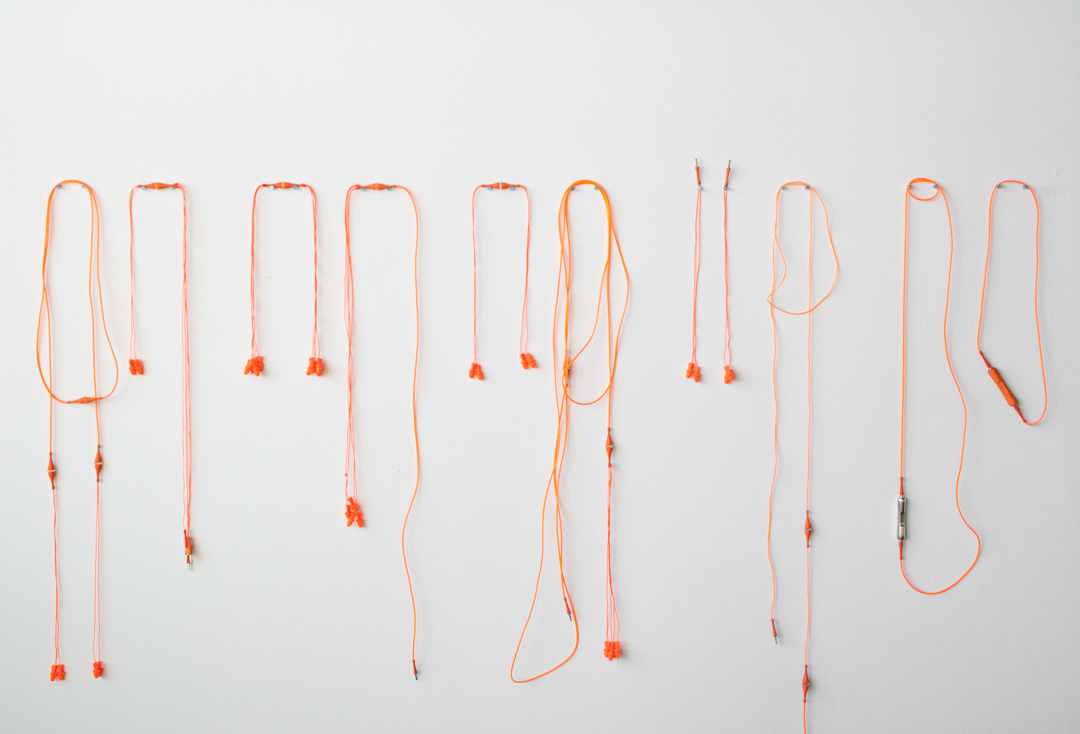

Plug Buffet

I pinned up a number of the pieces "buffet style" so the guys could pick and choose how they wanted to connect to each other and the objects in the room.

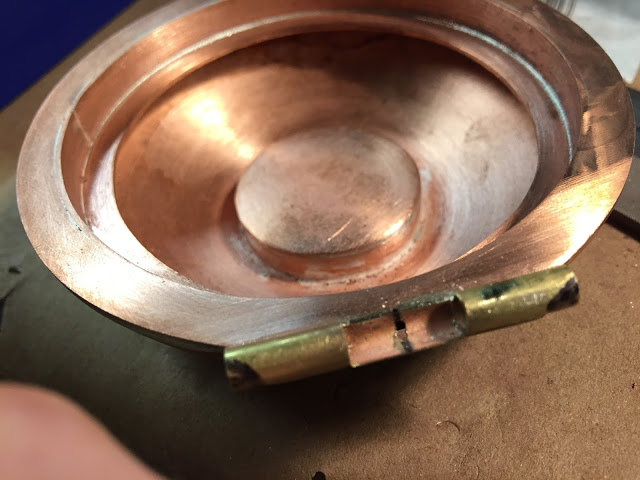

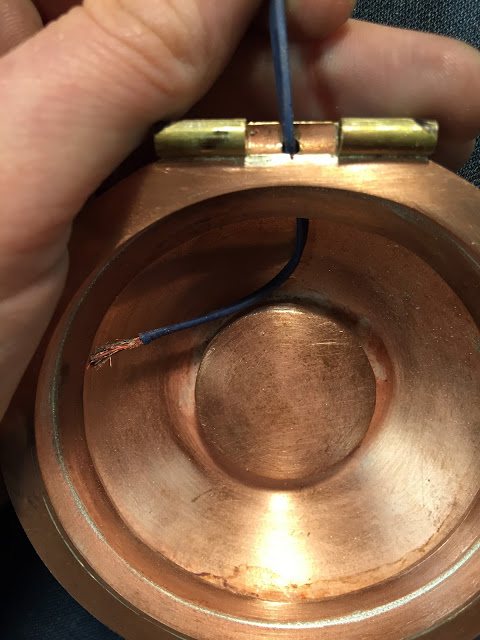

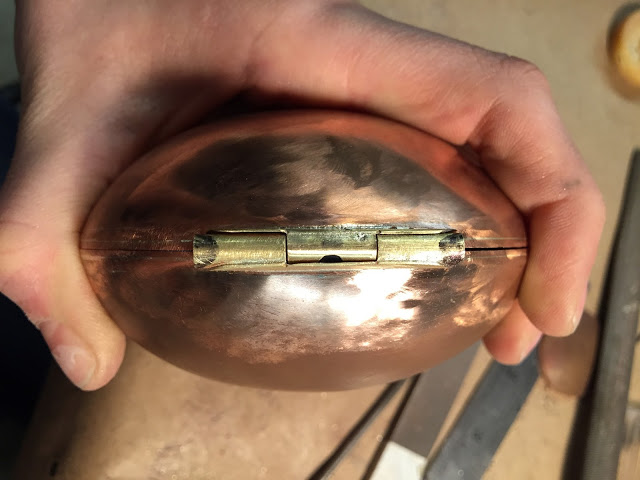

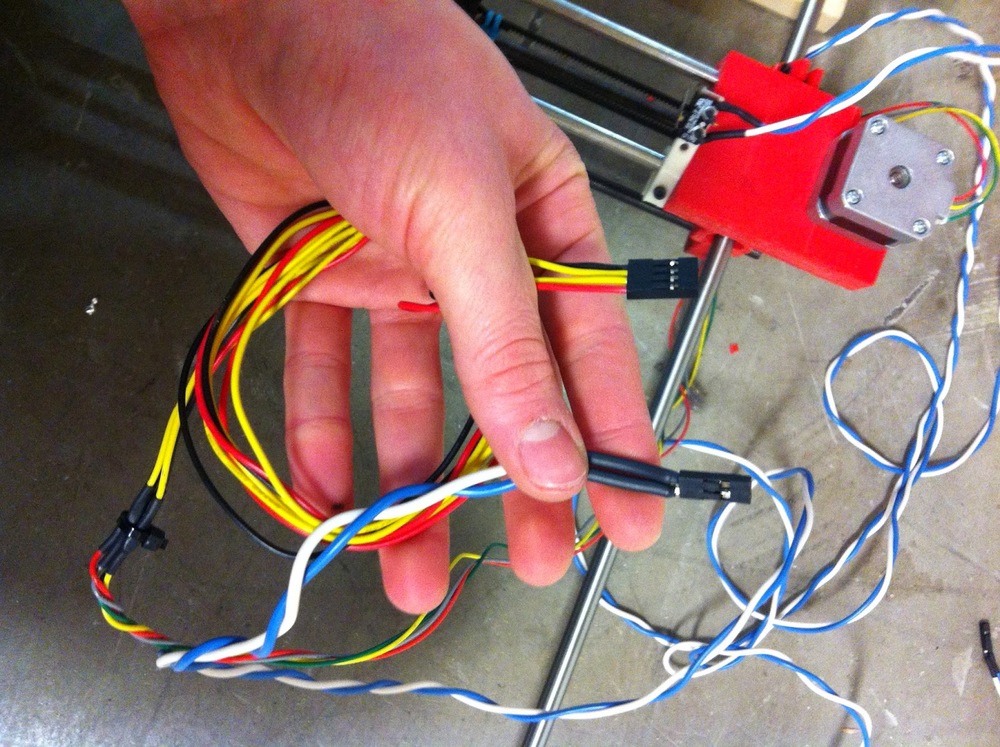

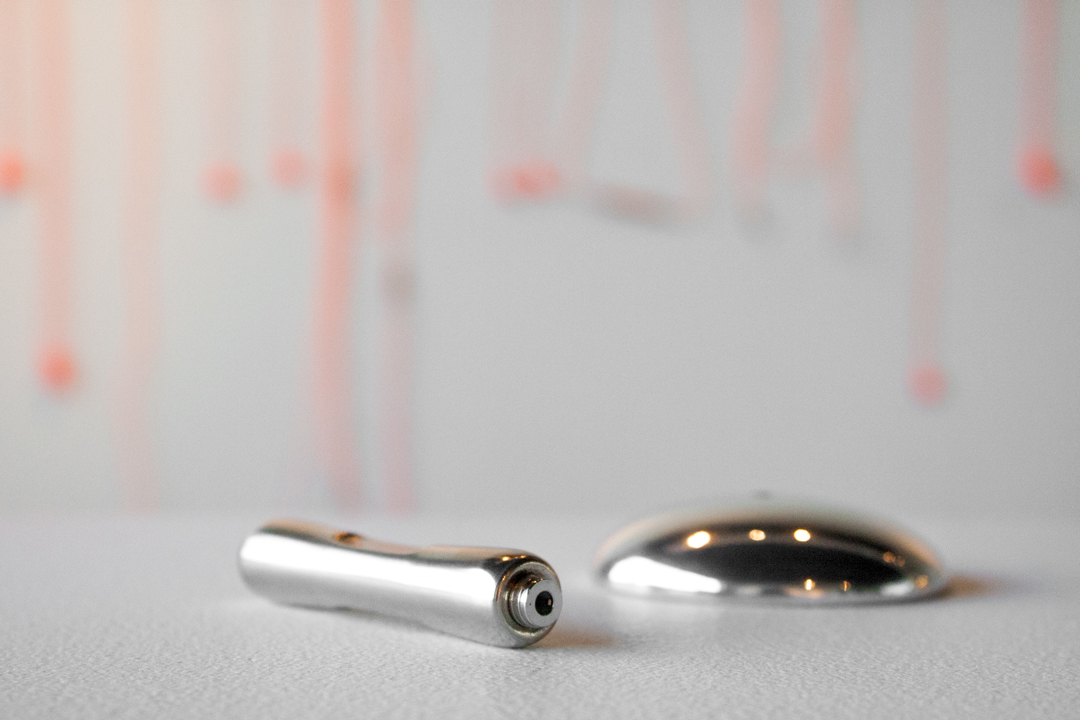

Sockets

I also had two of each of these sockets for the guys to plug the cords into if they desired to.

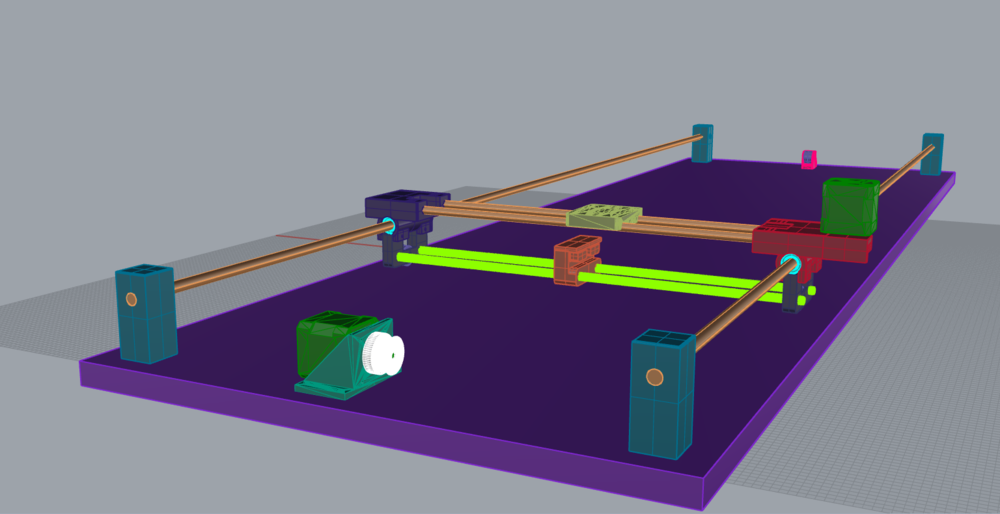

Teamwork

The Magic of Three

I never could have anticipated this arrangement. It was magical and gave me a whole new perspective on my work.

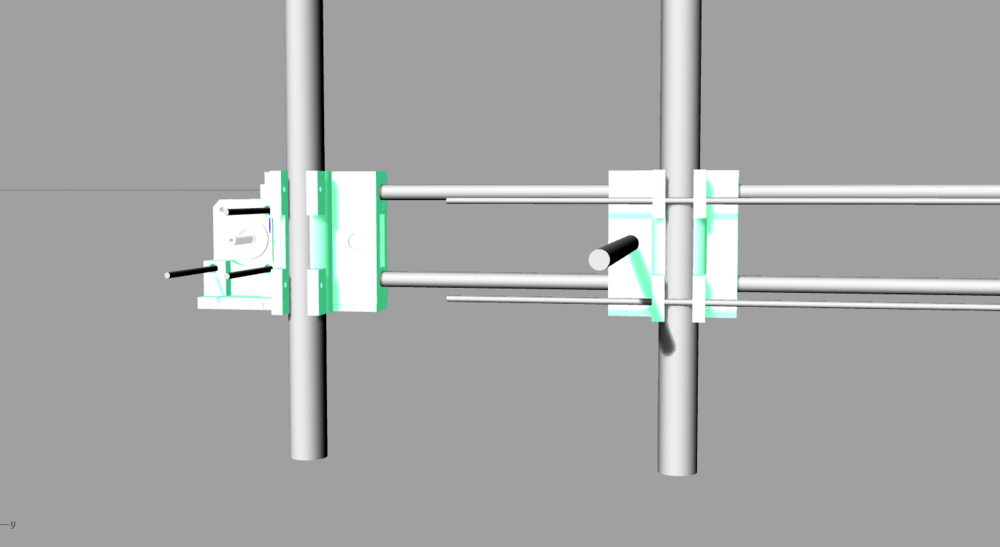

Plug Rope

For the guys, this piece turned into an exploration in movement. They started swaying their heads back in forth swinging the cord.

Bro-Love

Patrick "I've never been this close to your face before"