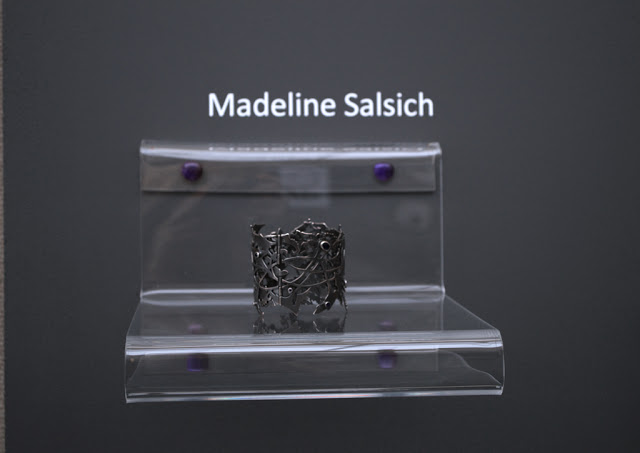

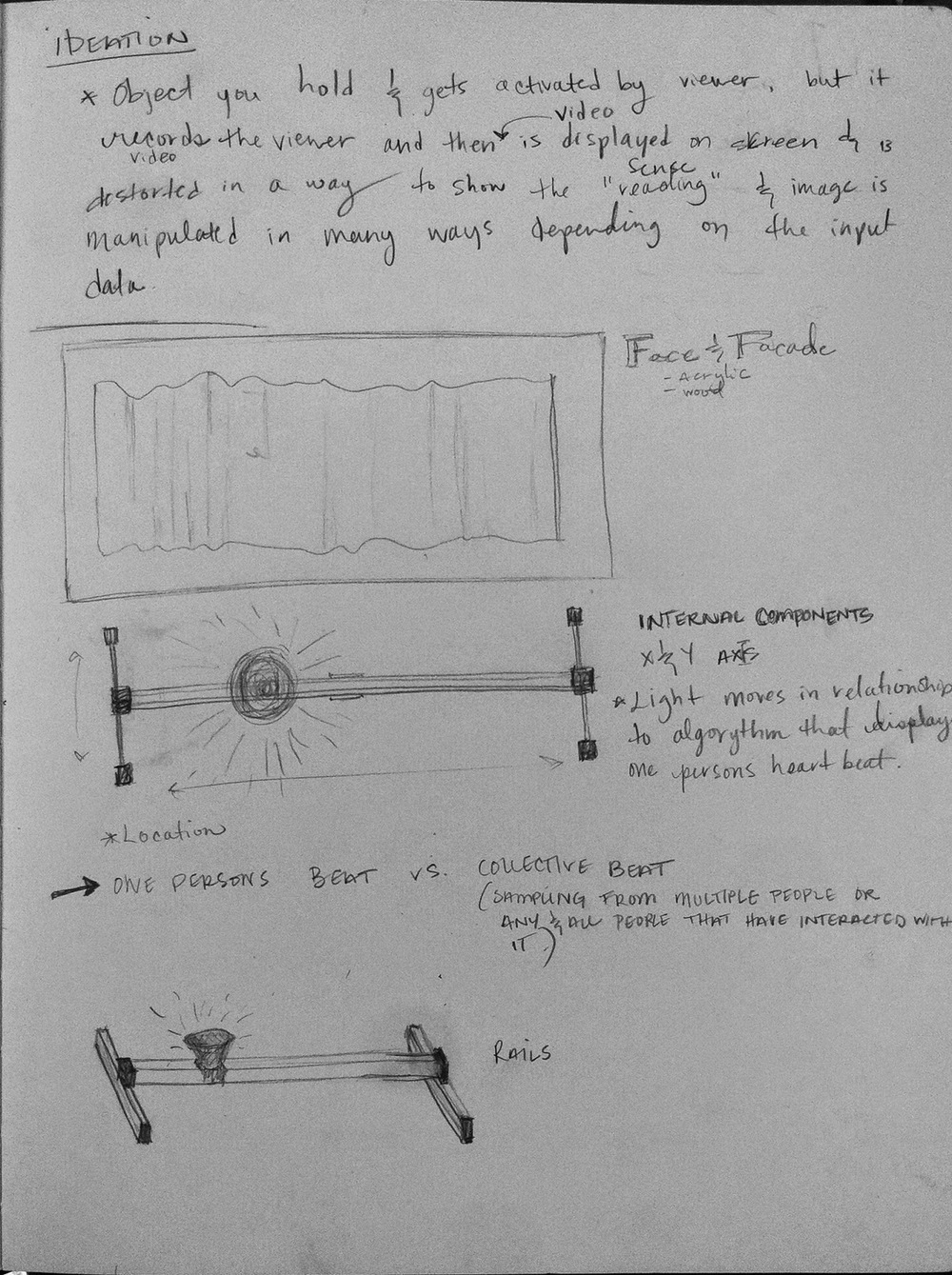

WOW. I got a lot accomplished on this thing last week and never posted about it... But that could also be because this is one of those moments where you make something and it's just how you want it, and you're super happy - but then you realize you lost sight of your intentions... WHOOPS! I forgot the holes for the cord :(. I might be able to improvise something though... Still thinking on how I will solve this problem without ruining my aesthetic.... TBC!

|

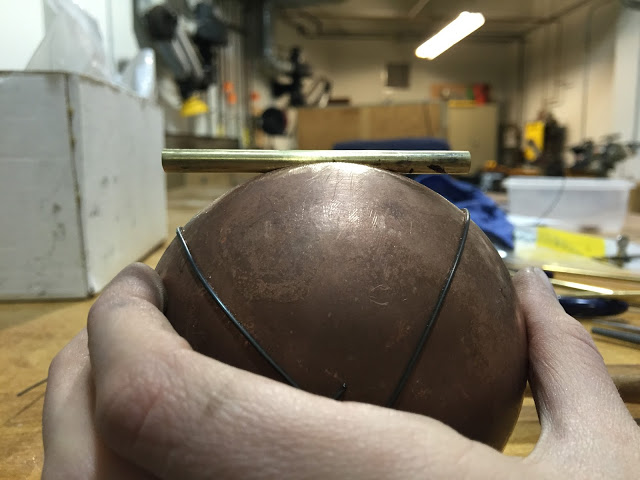

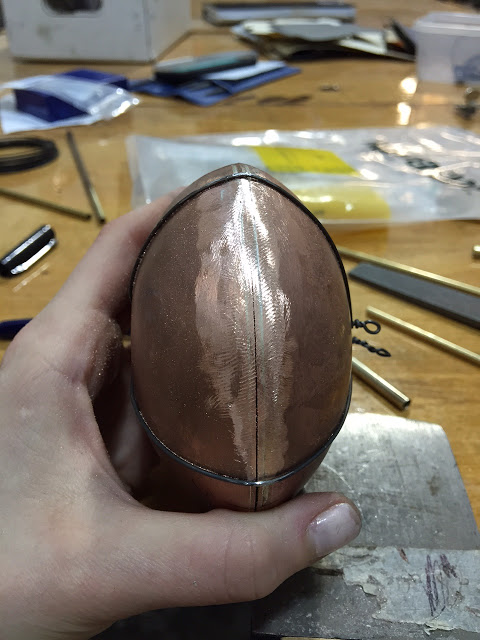

| Before the hinge.... |

|

| Yes, I did file out the entire hole for the cradle.... I am that insane. |

|

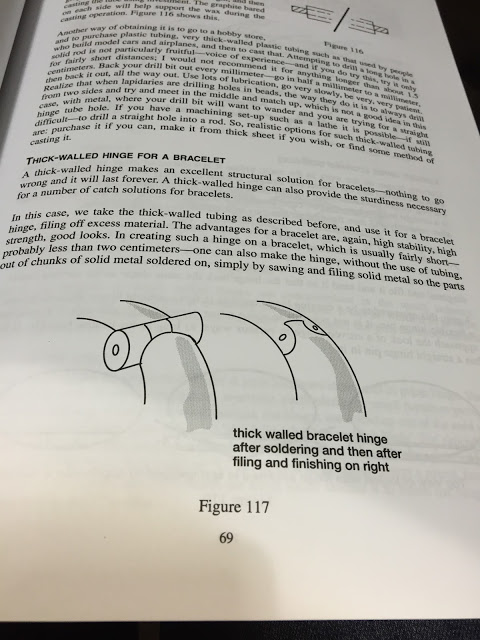

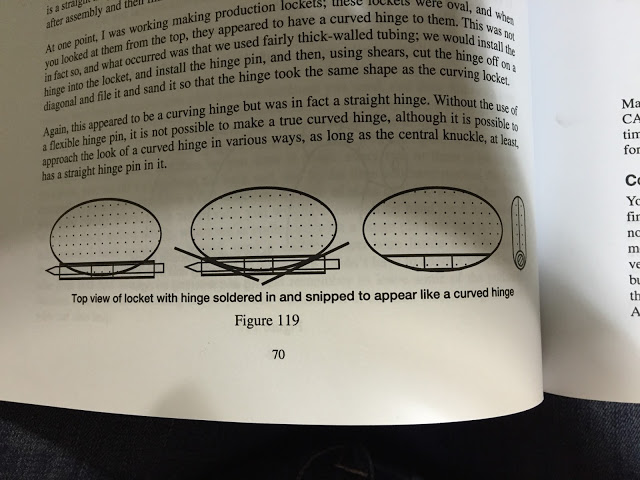

| A little book help never hurt. |

|

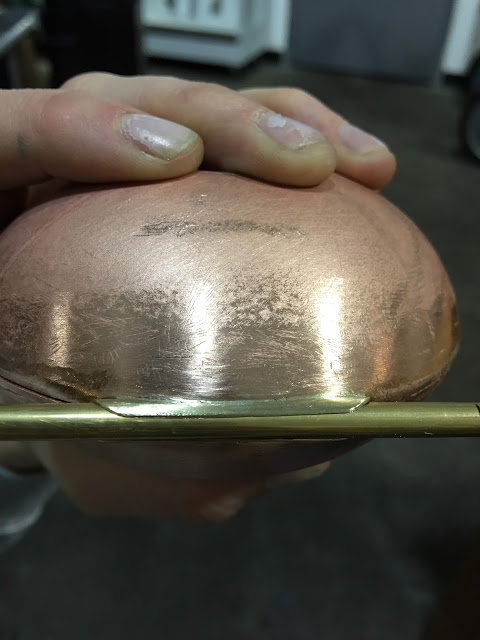

| I am using a couple magnets for the closing/clasping mechanism. |

|

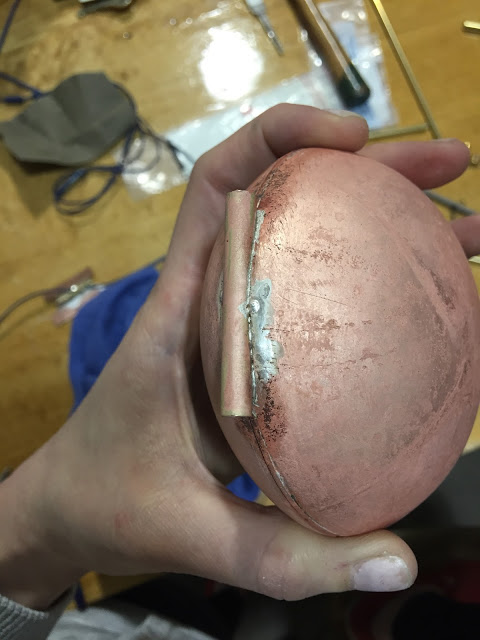

| Seams got a little messy, but I got it in one shot! |

|

| I soldered the hinge tubes on almost perfectly, with what I'm calling the "Tim Method" - marking position with a file, rather than soldering with the tubes and no-flo. |