e-NABLE Fellowship - Karuna's Trumpet Holder - Final Print

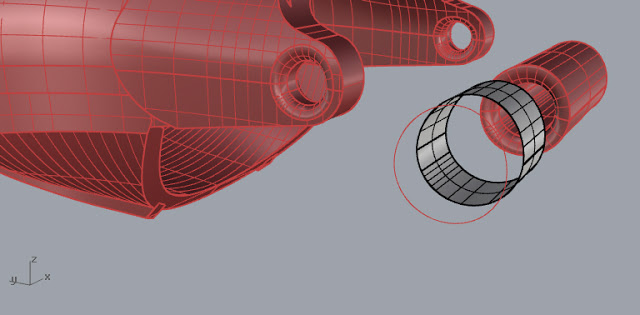

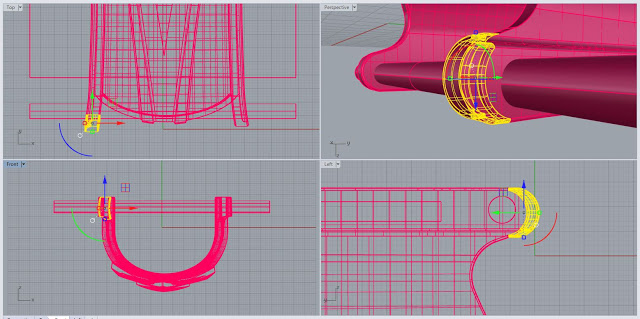

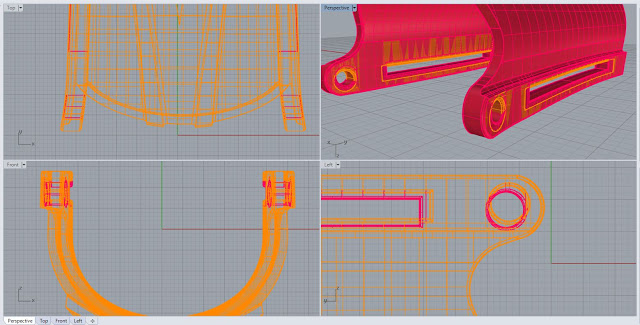

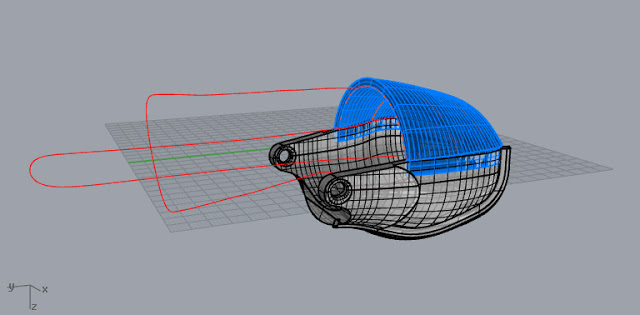

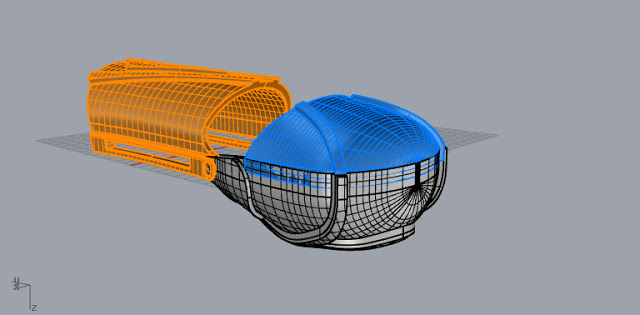

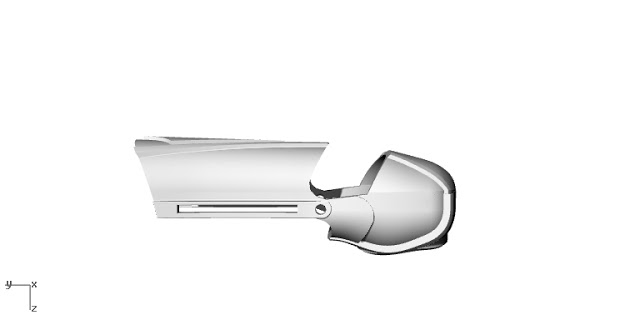

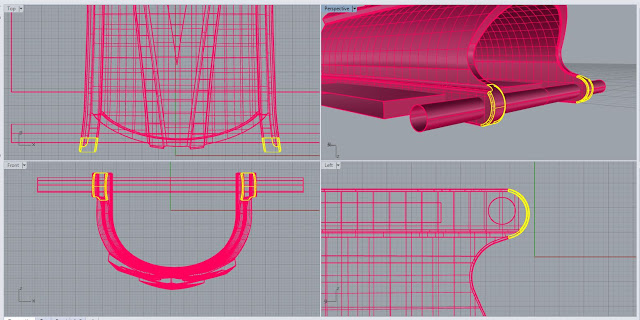

S100 - Rhino Gold - Bracelet to Ring

A friend of mine asked me to do something with this a long time ago - and I think I'm finally going to put in some work on it. Her mom had gotten her this bracelet when she was little and it unfortunately broke. I did a 3D scan of the object the other day and took some preliminary pictures of the ring... My plan is to design a ring using Rhino Gold, get it printed through Shapeways in wax, cast, and set the stone after. I've never done a ring design in Rhino Gold - or printed from Shapeways before - so this will be a nice low risk experiment.

S100 - Guitars for Vets

I ran into MDB in the hallway and he mentioned he was working on a project with some found guitars... We got to talking and he said that the project is a fundraiser for Guitars for Vets - Each year, Beverly Belfer from the Music Department organizes the donation of guitars to be painted or reworked into sculpture by artists for auction at an event in support of Guitars for Veterans. The guitars are supplied. While she would like for several of the guitars to remain playable, there is an opportunity to transform some into sculptural objects. - Broc Toft, another graduate student at UWM and I have decided to collaborate on a guitar sculpture... It's going to be fabulous.

We met last week Friday and started tearing apart a guitar - I took all the hardware, and he took the neck from our "rock-starred" guitar. I'm going to experiment with surfaces and pattern on most of the pieces I've taken... will do some work on the dark part of the body too... TBC

We met last week Friday and started tearing apart a guitar - I took all the hardware, and he took the neck from our "rock-starred" guitar. I'm going to experiment with surfaces and pattern on most of the pieces I've taken... will do some work on the dark part of the body too... TBC

e-NABLE Fellowship - Karuna's Trumpet Holder - Final Design Release

...and that's a wrap! Like with anything I've ever made before, I feel like this is object is one I could keep designing forever, over and over, re-doing all of the components until it's perfect, but sometimes you've just got to say "Hey - this is great! 1st iteration done!" and take a break for a little while. I've had such a great time working on this project. I never could have anticipated the feeling of accomplishment associated with designing for the e-NABLE community. Thank you everyone who has made this fellowship possible!

You can find the final designs on Thingiverse and Youmagine.

You can find the final designs on Thingiverse and Youmagine.

e-NABLE Fellowship - Karuna's Trumpet Holder - Scalable .stl

As I am getting prepared to release the files, I've begun to create scalable versions of all the Trumpet Adaptive Device components. It's been kind of challenging for a few of the components because I hadn't thought about this being needed at first... so I haven't modified them in the "right" way, but they will work just fine. I will definitely keep this in mind in the future for any other scalable objects I make.

e-NABLE Fellowship - Karuna's Trumpet Holder - Final Revisions

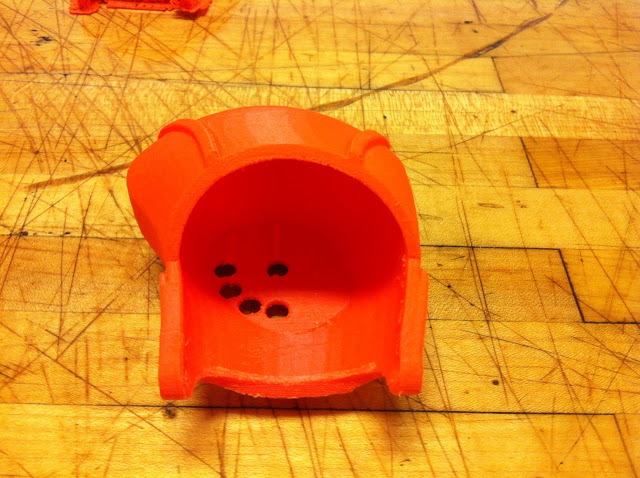

Revised Gauntlet |||||| The functional parts of the gauntlet needed a little bit more attention, specifically strength. I attempted to extend the surface slightly to increase the amount of material around the hole, but it wasn't working right. I finally decided to simply adjust the location of the hole and also adjusted the size of the Velcro slot to be more in line with the stock size of the material.

Revised Palm ||||||| I changed the placement of the holes for rotating the palm on the trumpet holder. The previous holes were estimations, but now the holes are custom to Karuna's liking.

|

| closed up the old holes |

|

| The measurement markings for adjusting the holes to fit Karuna's needs. |

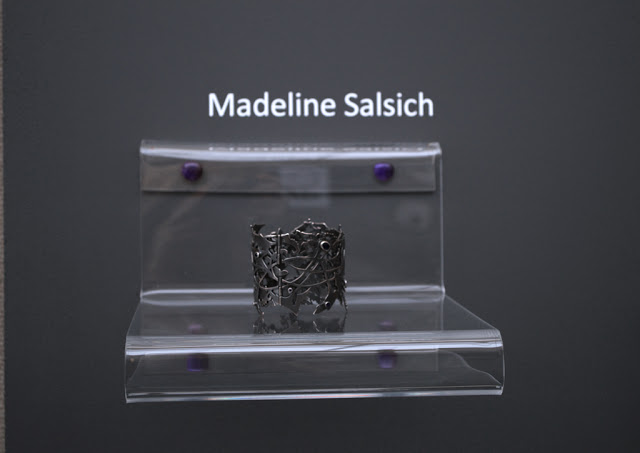

S100 - UWM @ Morning Glory - FORM event photographs

Here are some images I took of the show this past weekend at Morning Glory. FORM was intended to showcase a cross-section of work from recent UWM alumni. Each object represents an aspect of their individual creative practice that was formed in the Jewelry and Metalsmithing program at UWM. Find more information at the exhibition website > here.

We made all the displays custom for this show... which was a lot of work, but it surely paid off... I think we had one of the best looking booths at the event. There is still definitely room for improvement, but overall I'm impressed we were able to pull it off in essentially a week.

e-NABLE Fellowship - Karuna's Trumpet Holder - Interlocking Palm v4

S100 - Morning Glory Display - Part 3

A few of the pieces in the show required custom displays - including these necklaces by Clarissa Halat. I drew up a few different "necks" and acrylic glued them together. Eventually they were sandblasted and mounted on bent acrylic displays. This probably wasn't the best solution for these pieces, but it had to do with the time constraint.

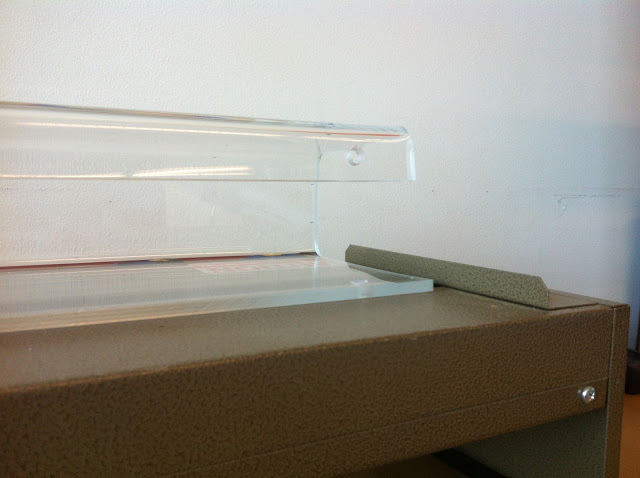

S100 - Morning Glory Display - Part 2

Frankie got a bunch of acrylic cut to size for our shelves. After laser cutting a few details into the small pieces, I started to bend all of the table/shelf accessories for holding rings, cuffs, necklaces etc. Each of these small displays took about 45 minutes to make... You've got to have a lot of patience to wait for the heating element to gently heat the piece, but be careful not to over heat the piece (so it's hard to multi-task while bending) and cause bubbling. The bigger pieces took longer - about 1 hour...

S100 - UWM @ Morning Glory Fine Art Craft Fair

I was given the opprotunity to organize, curate and execute a juried alumni exhibition for the Morning Glory Fine Art Craft Fair (more info: wdcc.org), so OF COURSE I said yes. I've participated in craft fairs before, but I've never run a juried exhibition, so that is very exciting to me.

One thing that I really miss about participating in events with Studio303, is organizing and planning shows, and interacting with the community.

So far, I've created a call for entry, designed an exhibition postcard, created a website, helped design a display, and started fabricating display... and much more... Hope you stop by! August 8-9th 10AM - 5PM at the Marcus Center for the Performing Arts.

One thing that I really miss about participating in events with Studio303, is organizing and planning shows, and interacting with the community.

So far, I've created a call for entry, designed an exhibition postcard, created a website, helped design a display, and started fabricating display... and much more... Hope you stop by! August 8-9th 10AM - 5PM at the Marcus Center for the Performing Arts.

S100 - Morning Glory Display - Part 1

I did some experimenting with the laser cutter to cure powder coat on acrylic for the Morning Glory display... although my results were pretty spotty, I'd be interested in trying to refine my ability to do this process in the future. For the final display, we went with the cut and engraved only, skipped the powder coat.

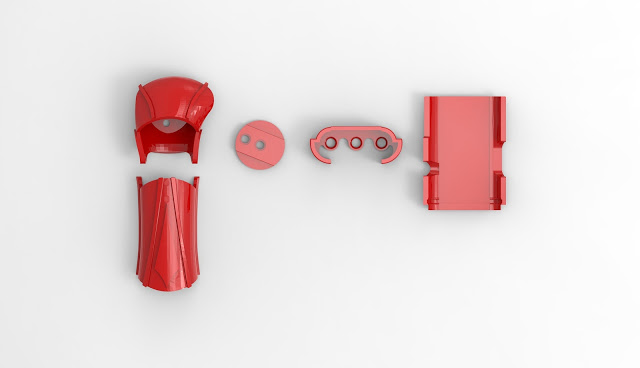

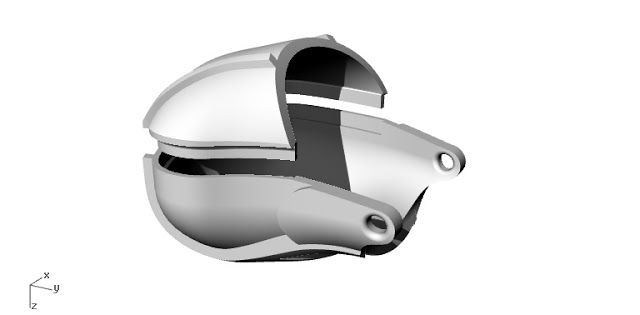

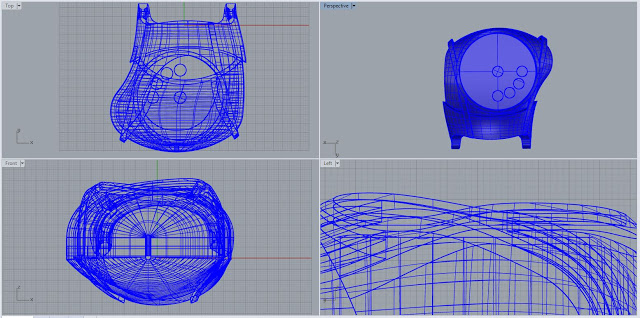

e-NABLE Fellowship - Karuna's Trumpet Holder - Rendered in Keyshot

I am rendering a few images for my portfolio and thought I would share... Oh, Keyshot, you are fabulous.

|

| I couldn't resist rendering one image in a metallic finish. |

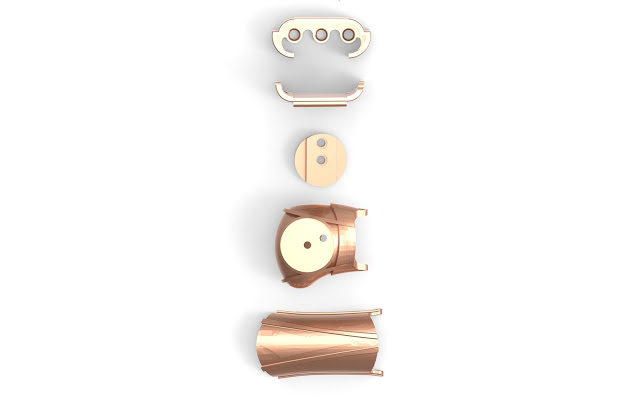

e-NABLE Fellowship - Karuna's Trumpet Holder - Prep for Karuna's Fitting

I finished up assembling the trumpet adaptive device, just in time for Karuna's fitting. I had about 15 minutes to snap a few quick shots before he arrived.

|

| It fits in the case! |

|

| All of the parts |

|

| Palm and gauntlet with dovetail for adapting to trumpet holder. |

|

| The orange piece (main) goes on first... |

|

| Followed by the black piece (bottom). |

|

| Ta-da! |

e-NABLE Fellowship - Karuna's Trumpet Holder - Assembling Parts for Fitting

|

| View of my work station today.... Definitely the most "handwork" I've done so far on this project - it was great! |

|

| I added padding to the gauntlet and wove the Velcro through the slots, but left enough extra to make modifications for when Karuna comes to the DCRL for the fitting. |

|

| Assembling the dovetail attachment. |

|

| Karuna needed to take his trumpet back today, so I made sure to document the pieces on his trumpet really well so that I could have a few shots with the device in place. |

|

| I realized during the documentation process that the holes for the angled mechanism were put on the wrong side - so I modified the piece for the fitting with Karuna by drilling a new hole. |

e-NABLE Fellowship - Karuna's Trumpet Holder - Printing Experiments Conclude....

e-NABLE Fellowship - Karuna's Trumpet Holder - Hand Progress - Part 7

e-NABLE Fellowhsip - Karuna's Trumpet Holder - Parts & Parts

Karuna is coming to the DCRL in a couple of days to try on the adaptive device to see if there needs to be further modifications for size. I've started piecing together a couple palm/gauntlet sets, so that he can have a few options for fit. This is the most recent pairing - most up to date with most modifications:

|

| v1 of the palm, v4 of the dovetail and v2 of the gauntlet. I thought this was it - but it wasn't - I made the wrong size holes in the palm piece and it was also super thin and too flexible. |

|

| v3 of gauntlet - 4 holes for adjusting the angle of dovetail - above is in position 2. I still have to add some cushioning material on the inside, and will cut a few slots for Velcro. |

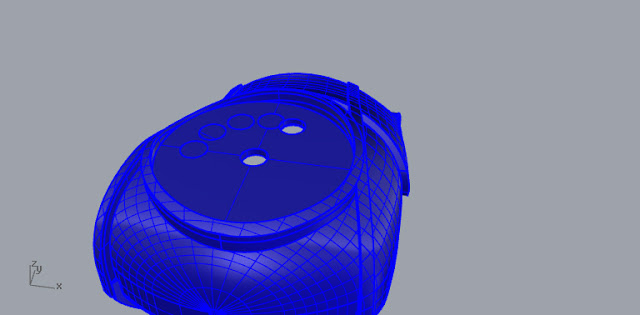

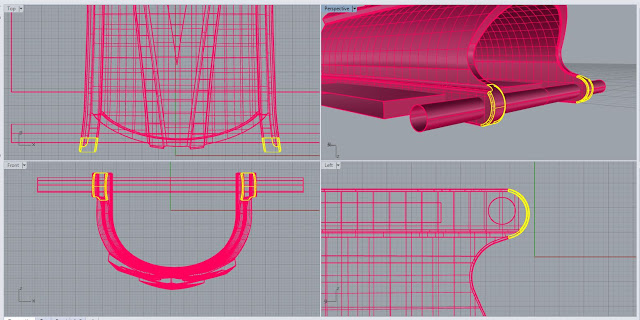

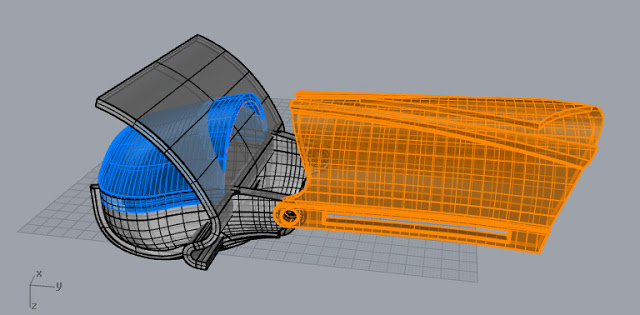

e-NABLE Fellowship - Karuna's Trumpet Holder - Palm v3

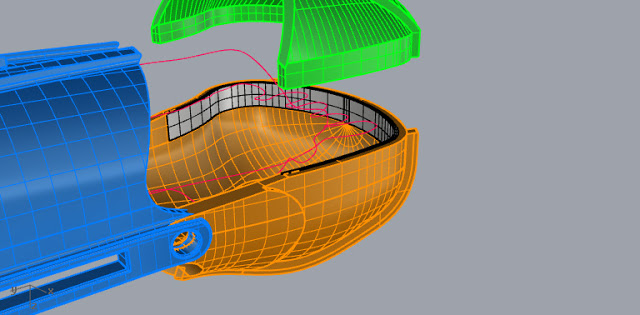

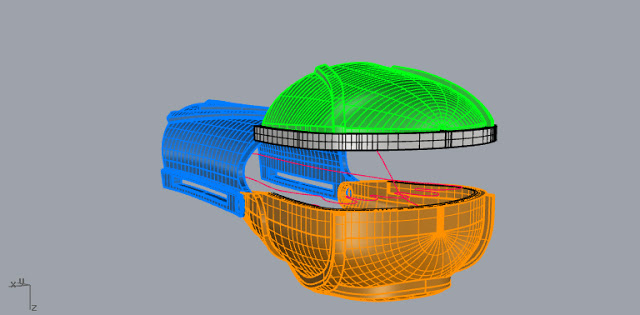

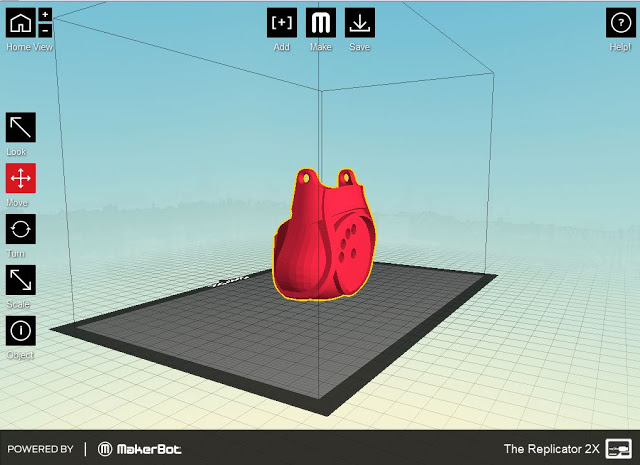

I spent most of today designing version 3 of the palm attachment. Frankie and I had talked about the potential to eliminate the Velcro on the palm attachment by making a cap for the back - like a socket. The challenge now is figuring out the best way to print this object on a Makerbot... (This leads me to think another iteration is necessary - version 4 will have two parts that interlock.) I am test printing two of these hand pieces currently - one printing on it's "head" and another printing on it's "back." ...Wish me luck!

|

| I created this top part the exact same way as the bottom - curve network & extruded surface & offset surface solids. |

|

| I borrowed wrist curve from gauntlet to create profile. |

|

| This profile reminds me of Darth Vader - HA! |

|

| printing on it's head - with supports - probably will fail, but why not try? |