Last week was the first week of class for Fall 2015... I received homework in my

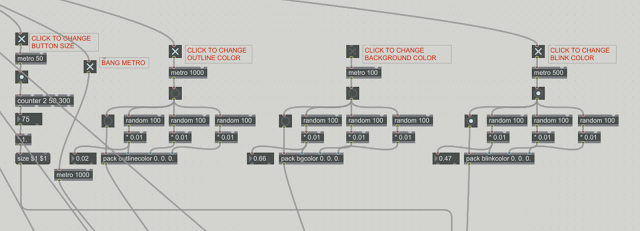

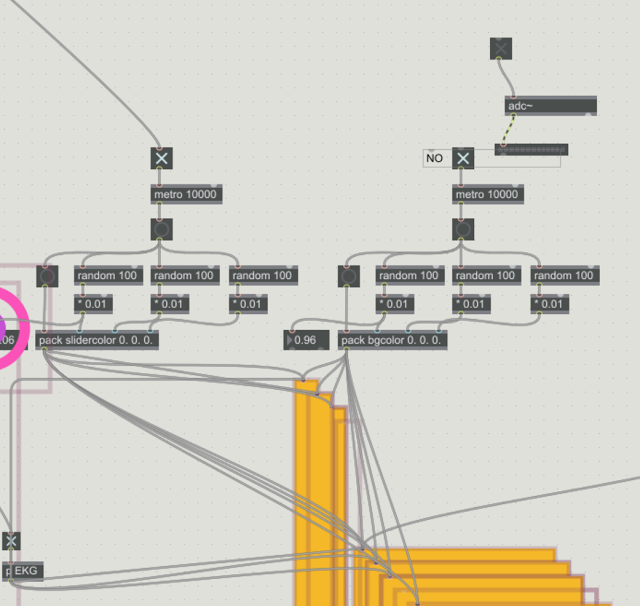

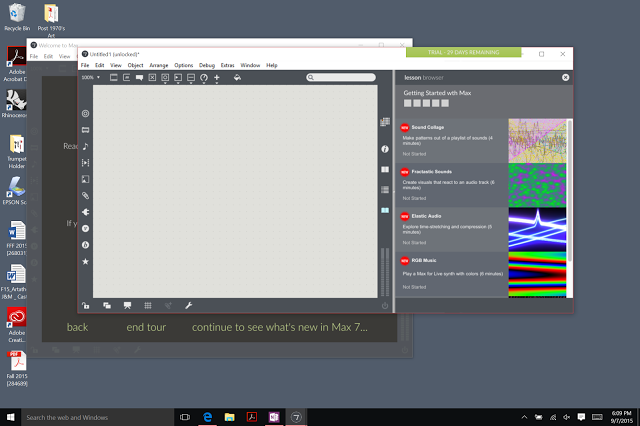

Interactive and Multimedia Art class; download Max 7, and do tutorials 1-3 for Max... Here's a brief summary of what the tutorials covered:

Tutorial 1; introduced object boxes, inlets, message boxes, and comment boxes, patchcords, how to unlock and lock patches, and use the Reference functions.

Object boxes operate like miniature programs within the larger environments.

Message boxes send messages to objects, and can operate as either commands or control data. Use commas by adding a backslash before, or the result is a new line of text.

Comment boxes are used to add text to controls, such as "click me."

Max programs function by passing messages between objects.

Tutorial 2; introduced bang! message (do the thing you do!), and spatial organization of messages: information is sent right to left when there are multiple messages connected with a bang!

Tutorial 3; numeric data: numbers and lists: integer and floating point number boxes, pack objects and pak objects. $ before a number in a message allows you to have a changing numeric input.

-------------------------------

I also noticed that Max has a series of tutorials built into the program... I may check some of these out during the coming weeks...